Metal Stamped Parts for the Automotive Industry

Leave a CommentThroughout our more than 50 years of business, the engineers at Keats Manufacturing have been producing the highest quality custom metal stampings, wire forms, and assemblies for a wide range of industries. Listed below are several examples of custom metal stamped parts for automotive that Keats has manufactured.

Positioning Sensor for Steering Wheel

Keats was sent a 0.0238” thick phosphor bronze material and our engineering team was tasked with turning that raw material into terminals to be used in numerous automotive steering wheel sensors.

Using our precision custom stamping services, Keats was able to design, build, and package one million of these terminals and ship them to the client’s location in Europe. In addition, these terminals were also plated with bright tin to increase their corrosion resistance. The reel-to-reel plating process that we performed ensured uniform deposition of the coating and significantly helped to decrease overall cost.

Fuel Injection Steel Shield for Engines

An automotive manufacturer provided Keats with a print and a .DWG AutoCAD file that contained specifications of a fuel injection steel shield that was required for use in automotive engines.

An automotive manufacturer provided Keats with a print and a .DWG AutoCAD file that contained specifications of a fuel injection steel shield that was required for use in automotive engines.

Using DCC programmable CMMs, our precision stamping process allowed us to manufacture one million parts from 1008/1010 cold rolled steel with tight tolerances of 0.003”. Zinc phosphate coating was then applied because of their paint bonding characteristics. We were able to complete and deliver this order with a turnaround time of 15 days.

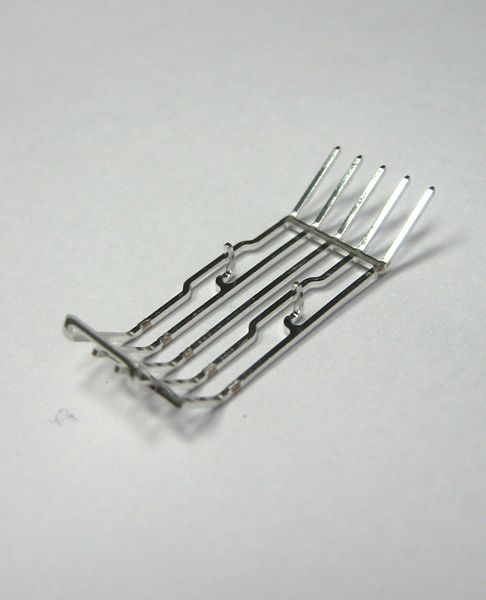

Terminal Wire Forms for Sensors

One client came to Keats with a need for terminals to be used in sensors for various automotive parts. Starting with copper alloy wires with a thickness of 0.082”, the Keats engineering team leveraged our in-house AutoCAD and tooling machinery to achieve tolerances of 0.001” to manufacture 25,000 terminal wire forms with chamfered ends. The entire process, including delivery, took 30 days from start-to-finish.

One client came to Keats with a need for terminals to be used in sensors for various automotive parts. Starting with copper alloy wires with a thickness of 0.082”, the Keats engineering team leveraged our in-house AutoCAD and tooling machinery to achieve tolerances of 0.001” to manufacture 25,000 terminal wire forms with chamfered ends. The entire process, including delivery, took 30 days from start-to-finish.

More Products for Automotive Applications

To see where else Keats’ metal stamped products are used throughout the automotive industry, check out our interactive infographic.