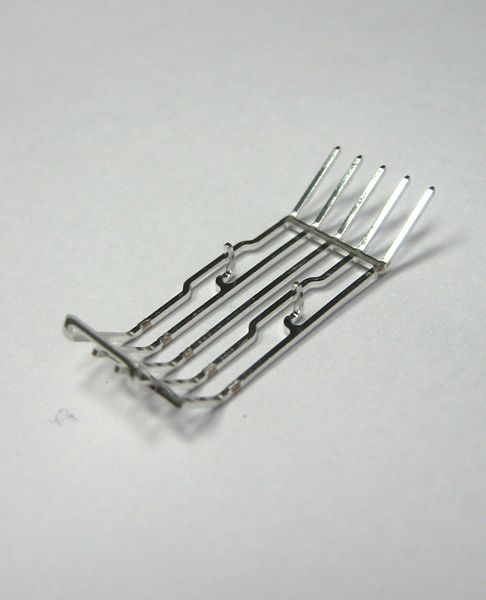

The terminal seen in the picture was manufactured for automotive steering position sensors from a 0.0238” thick phosphor bronze material.

In addition to designing and building the terminals, Keats Manufacturing Co. also packaged this product in special packaging and delivered to the client’s location in Europe. One million terminals were manufactured with our precision stamping services. These terminals were plated with bright tin for high corrosion resistance. The reel to reel plating process we performed ensured uniform deposition of tin and significant cost savings to the customer.

For additional information on this portfolio, please refer to the table below. We also encourage you to check out our eBook, Design Tips for Automotive Contacts & Terminals.

Custom Phosphor Bronze Terminal Stamping

Product Description

This phosphor bronze terminal is used in numerous automotive steering wheel sensors

Capabilities Applied/Processes

Stamping

Tightest Tolerance

0.002 inches

Material Thickness

0.0238 inches

Material Applied

Bright tin plating

Material Used

#510 Phosphor Bronze

Material Finish

Plated with Tin

Secondary Operations Applied

Reel to Reel Plating

Industry for Use

Automotive

Volume

1,800,000 pieces

Delivery Time

JIT

Delivery Location

Europe

Standards Met

Customer supplied print, .DWG AutoCAD file

Product Name

Terminal

Project Scope

Design and build terminal for automotive steering position sensor with special packaging

Design Work

AutoCAD design software to design stamping die