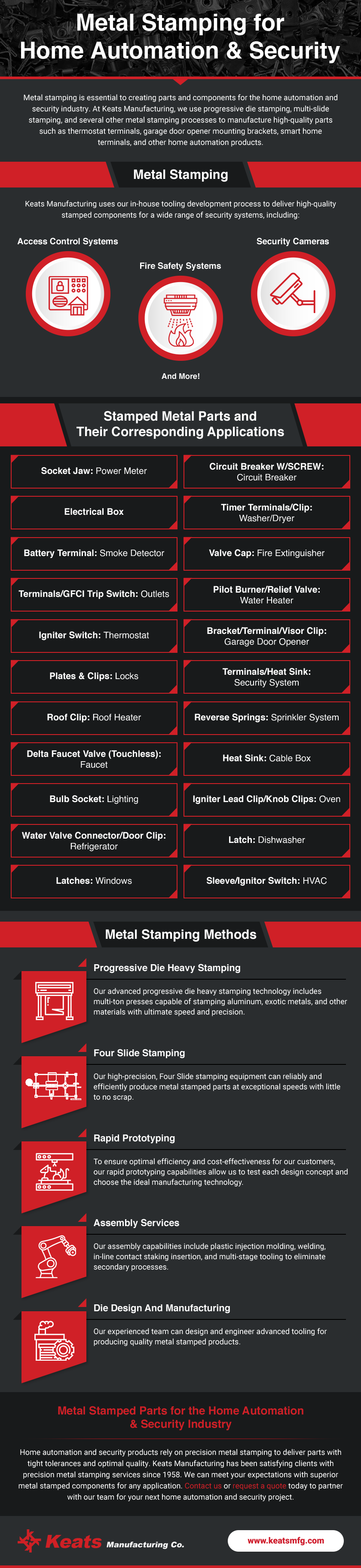

Metal stamping is essential to creating parts and components for the home automation and security industry. At Keats Manufacturing, we use progressive die stamping, multi-slide stamping, and several other metal stamping processes to manufacture high-quality parts such as thermostat terminals, garage door opener mounting brackets, smart home terminals, and other home automation products.

Metal Stamping

Metal stamping includes a variety of metal forming techniques used to convert a flat metal sheet into the desired shape. It includes processes like piercing, bending, punching, blanking, and several other forming functions. Security system components and complex appliances depend on metal stamped parts formed from high-quality materials to perform long-term.

Keats Manufacturing uses our in-house tooling development process to deliver high-quality stamped components for a wide range of security systems, including:

- Access Control Systems

- Fire Safety Systems

- Security Cameras

- And More!

Stamped Metal Parts and Their Corresponding Applications

At Keats Manufacturing, we rely on metal stamping to form various parts. The following applications use our metal stamped components:

- Socket Jaw: Power Meter

- Circuit Breaker W/SCREW: Circuit Breaker

- Electrical Box

- Timer Terminals/Clip: Washer/Dryer

- Battery Terminal: Smoke Detector

- Valve Cap: Fire Extinguisher

- Terminals/GFCI Trip Switch: Outlets

- Pilot Burner/Relief Valve: Water Heater

- Igniter Switch: Thermostat

- Bracket/Terminal/Visor Clip: Garage Door Opener

- Plates & Clips: Locks

- Terminals/Heat Sink: Security System

- Roof Clip: Roof Heater

- Reverse Springs: Sprinkler System

- Delta Faucet Valve (Touchless): Faucet

- Heat Sink: Cable Box

- Bulb Socket: Lighting

- Igniter Lead Clip/Knob Clips: Oven

- Water Valve Connector/Door Clip: Refrigerator

- Latch: Dishwasher

- Latches: Windows

- Sleeve/Ignitor Switch: HVAC

Metal Stamping Methods

Keats Manufacturing relies on various precision stamping methods to produce parts and components for home security and automation products. These include:

- Progressive Die Heavy Stamping. Our advanced progressive die heavy stamping technology includes multi-ton presses capable of stamping aluminum, exotic metals, and other materials with ultimate speed and precision.

- Four Slide Stamping. Our high-precision, Four Slide stamping equipment can reliably and efficiently produce metal stamped parts at exceptional speeds with little to no scrap.

- Rapid Prototyping. To ensure optimal efficiency and cost-effectiveness for our customers, our rapid prototyping capabilities allow us to test each design concept and choose the ideal manufacturing technology.

- Assembly Services. Our assembly capabilities include plastic injection molding, welding, in-line contact staking insertion, and multi-stage tooling to eliminate secondary processes.

- Die Design And Manufacturing. Our experienced team can design and engineer advanced tooling for producing quality metal stamped products.

Metal Stamped Parts for the Home Automation & Security Industry

Home automation and security products rely on precision metal stamping to deliver parts with tight tolerances and optimal quality. Keats Manufacturing has been satisfying clients with precision metal stamping services since 1958. We can meet your expectations with superior metal stamped components for any application. Contact us or request a quote today to partner with our team for your next home automation and security project.