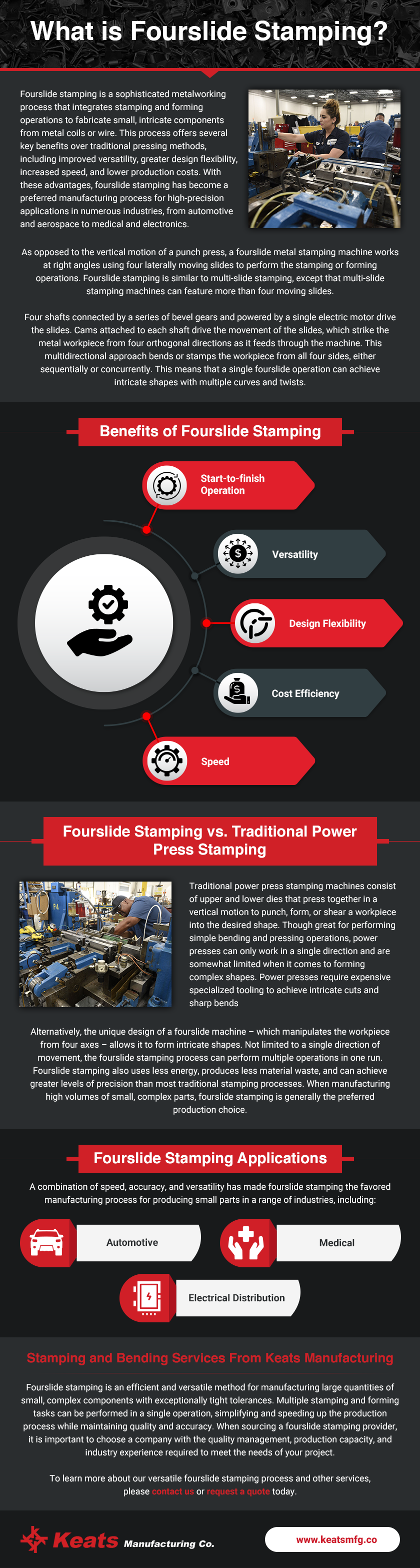

Fourslide stamping is a sophisticated metalworking process that integrates stamping and forming operations to fabricate small, intricate components from metal coils or wire. This process offers several key benefits over traditional pressing methods, including improved versatility, greater design flexibility, increased speed, and lower production costs. With these advantages, fourslide stamping has become a preferred manufacturing process for high-precision applications in numerous industries, from automotive and aerospace to medical and electronics.

As opposed to the vertical motion of a punch press, a fourslide metal stamping machine works at right angles using four laterally moving slides to perform the stamping or forming operations. Fourslide stamping is similar to multi-slide stamping, except that multi-slide stamping machines can feature more than four moving slides.

As opposed to the vertical motion of a punch press, a fourslide metal stamping machine works at right angles using four laterally moving slides to perform the stamping or forming operations. Fourslide stamping is similar to multi-slide stamping, except that multi-slide stamping machines can feature more than four moving slides.

Four shafts connected by a series of bevel gears and powered by a single electric motor drive the slides. Cams attached to each shaft drive the movement of the slides, which strike the metal workpiece from four orthogonal directions as it feeds through the machine. This multidirectional approach bends or stamps the workpiece from all four sides, either sequentially or concurrently. This means that a single fourslide operation can achieve intricate shapes with multiple curves and twists.

Benefits of Fourslide Stamping

- Start-to-finish operation: Fourslide stamping machines perform multiple forming and stamping tasks in a single operation. This allows for start-to-finish completion of a part that would otherwise require one, or several, secondary operations.

- Versatility: By manipulating the workpiece from several directions, fourslide stamping can produce complex parts with intricate details, twists, and curves. This metalworking process is also suited for a wide range of materials, including copper, steel, aluminum, bronze, brass, and more.

- Design flexibility: With traditional press operations, modifying a part design can be expensive and time-consuming, or otherwise necessitate the manufacture of an entirely new die. Alternatively, fourslide stamping allows the machine to perform several motions, and thus can accommodate design changes with fairly simple adjustments to individual sliding tools.

- Cost efficiency: Compared with most traditional metalworking methods, the fourslide stamping process uses materials more efficiently and generates less waste. This is especially beneficial when fabricating components from expensive material. Fourslide stamping often requires a lower tooling investment and can achieve production rates of almost 15,000 pieces per hour depending on part complexity. Combined, these advantages make fourslide stamping one of the most cost-efficient options for high-volume production of small, intricate parts.

- Speed: Fourslide stamping operates at very high speeds, often in tandem with other operations. In addition to reducing costs, this feature enables a much faster turnaround.

Fourslide Stamping vs. Traditional Power Press Stamping

Traditional power press stamping machines consist of upper and lower dies that press together in a vertical motion to punch, form, or shear a workpiece into the desired shape. Though great for performing simple bending and pressing operations, power presses can only work in a single direction and are somewhat limited when it comes to forming complex shapes. Power presses require expensive specialized tooling to achieve intricate cuts and sharp bends

Traditional power press stamping machines consist of upper and lower dies that press together in a vertical motion to punch, form, or shear a workpiece into the desired shape. Though great for performing simple bending and pressing operations, power presses can only work in a single direction and are somewhat limited when it comes to forming complex shapes. Power presses require expensive specialized tooling to achieve intricate cuts and sharp bends

Alternatively, the unique design of a fourslide machine – which manipulates the workpiece from four axes – allows it to form intricate shapes. Not limited to a single direction of movement, the fourslide stamping process can perform multiple operations in one run. Fourslide stamping also uses less energy, produces less material waste, and can achieve greater levels of precision than most traditional stamping processes. When manufacturing high volumes of small, complex parts, fourslide stamping is generally the preferred production choice.

Fourslide Stamping Applications

A combination of speed, accuracy, and versatility has made fourslide stamping the favored manufacturing process for producing small parts in a range of industries, including:

- Automotive: Stamped metal components are used in almost every system of automotive vehicles, from the engine to the brakes. Fourslide stamping can efficiently produce large numbers of identical parts with uniform quality, making it perfect for high-volume manufacturing in the automotive industry. Examples of stamped automotive components include battery cable connectors, HVAC parts, key fob terminals, brackets, clips, and fasteners.

- Medical: When it comes to medical component manufacturing, quality and precision must be carefully balanced with speed and efficiency to keep up with the rapid pace of technological advancements. Fourslide stamping is ideal for fast production of small, complex parts that pass strict medical-grade standards. Examples of fourslide-stamped medical components include device enclosures, implantable components, and jaw housings for surgical components.

- Electrical Distribution: In complex electrical grid applications, even the tiniest flaws in components can have catastrophic consequences. The electrical distribution industry relies on fourslide stamping for the production of consistently defect-free products with super-tight tolerances. A few examples of precision-stamped aerospace components include brackets, circuit breaker terminals, lead frames, socket jaws, and wire forms.

Stamping and Bending Services From Keats Manufacturing

Fourslide stamping is an efficient and versatile method for manufacturing large quantities of small, complex components with exceptionally tight tolerances. Multiple stamping and forming tasks can be performed in a single operation, simplifying and speeding up the production process while maintaining quality and accuracy. When sourcing a fourslide stamping provider, it is important to choose a company with the quality management, production capacity, and industry experience required to meet the needs of your project.

With over 60 years of experience in our field, Keats Manufacturing has become an industry-leading manufacturer of fourslide components, custom metal stampings, wire forms, and assemblies for a range of industries. As an ISO- and ITAF-certified provider, our customers can expect unparalleled levels of quality and precision in everything we manufacture. Equipped with three state-of-the-art facilities and in-house tooling design and development services, we have the skills and resources to meet practically any small metal stamping need, no matter how complex.

To learn more about our versatile fourslide stamping process and other services, please contact us or request a quote today.