Electrical Distribution Industry

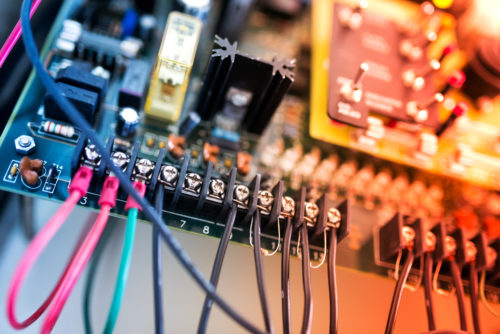

Discussions around the electrical industry frequently focus on power generation, but those discussions leave out an equally important sector: the distribution and transmission of energy. Parts from various industries, such as circuit breakers, distribution boxes, switches and lines/transformers, come together to perform vital functions within the electrical distribution industry. Without these key industries, it would be impossible to deliver electric power to users.

What We Do

At Keats Manufacturing, we appreciate the integral role our tooling plays within the electrical distribution industry. Our specialty is complex precision metal stamping, wire forming, and assembly. With our state-of-the-art stamping press and four-slide equipment, we construct the best tooling in the industry, working with projects from development through to completion. Quality parts come from quality tooling—and we stand behind our tooling with a lifetime guarantee. Parts we provide include:

- Terminals

- Brackets

- Clips

- Ground straps

- Contacts

- Shields

- Bushings

- Inserts

- Clamps

- Springs

- Covers

- Sleeves

- Washers

- Heat sinks

- Cases

- Antennas

- Plates

- Bus bars

- Socket jaws

- Fan blades

- Retainers

Applications

Our metal services are utilized in a variety of applications within the electrical distribution industry. Here are just a few areas to which we contribute:

Commercial and Residential Circuit Breakers

These essential products aid in keeping commercial and residential appliances operating safely, as they interrupt circuit flow if the appliance experiences issues such as overload or overcurrent. Without circuit breakers, appliances may become damaged or even explode, necessitating costly repairs.

Fuses and Fuse Boxes

Similarly, fuses help to prevent damage in the event of a current overload. These products conduct electrical flow through the circuits; if the current exceeds capacity, the fuse overheats and melts, shutting off the circuit and preventing a continuous flow of damaging electricity.

Electrical Panels and Boxes

Occasionally referred to as load centers, electrical panels are metal electrical service boxes that control the energy flow within an electrical system. They function by accepting the main electricity for any given building and moving the electrical current to the necessary circuits to ensure a steady distribution of energy.

Switches

Switches are a vital product for safe energy distribution and often strategically installed throughout distribution systems. These devices control the flow of electricity, enabling the redirection or complete cut-off of power. This makes it safer and easier to sectionalize, balance loads, or repair and upgrade electrical systems.

Outlets and Receptacles

Although these two terms are often used interchangeably, they serve two different functions. A power outlet is the single point of access where electronics connect with the branch circuit. The receptacle can be found on the front of the power outlet, where the user can insert the electronic plugs. Together, outlets and receptacles create a single unit with up to three plugs.

Distribution Relays

Another type of protective measure, distribution relays can be used in a variety of applications that require an instantaneous or timed response to overcurrents. For example, these products may be utilized to protect medium voltage distribution lines.

Power Meters

To assist with the efficient management of electrical distribution, power meters measure and monitor the output of energy within various systems. This makes it easier for both professionals and consumers to track their power usage.

Materials

We utilize a variety of materials to craft our tooling, including:

- Aluminum

- Brass

- Copper

- Phosphor bronze

- Silver

- Stainless steel

Additional/Secondary Services

At Keats, we offer a variety of secondary services to meet our clients’ needs including:

- Assembly

- Deburring

- Degreasing

- Plating

Why Keats Manufacturing?

Our decades of experience let us provide the highest levels of precision at affordable rates. In our state-of-the-art facilities, we meet key industry standards, including:

- ISO:9001

- ISO:14001

- TS 16949

Additionally, we utilize computer-aided design (CAD), quality control, and proper tooling to provide our customers with consistently high quality parts. To achieve process stability and repeatability, we regularly perform Cpk studies on all of our processes.

We focus primarily on high-volume projects and have the appropriate resources and machinery to efficiently fulfill large orders, making us the ideal choice for projects requiring mass production. We keep costs low by optimizing the use of raw materials and removing as much waste as possible from the production process. These steps enable us to offer more competitive pricing than other suppliers. For a more in-depth look at the ways in which we contribute to the electrical distribution industry, take a look at our infographic or download our eBook, “How to Add Keats to Your Supply Chain.”