Keats Manufacturing provides custom metal stampings of superior quality to a variety of specialty industries. Our team is backed by decades of experience and an informed understanding of the needs the industries that we serve. Our team can tackle complex projects ranging from intricate assemblies to small metal stampings and wire forms.

Customers have long looked to Keats to provide state-of-the-art technology, extreme efficiency, and a high level of quality control. Our team includes 25 of the most experienced die makers in the metal stamping business. Our other services – such as stamping, tapping/threading, forming, and assembly – provide end-to-end solutions for customers in the appliance industry and many others.

Small Metal Stamped Parts in the Appliance Industry

Our small metal stamped parts are contributing components to large, useful, and critical systems across a wide range of applications. Many manufacturers can produce the small metal stamped parts you need for your appliances, but quality in these parts may vary. Understanding the variability in part quality from one supplier to another is critical.

Keats has stood the test of time and remained an industry leader since 1958. You’ll never need to worry about our technical capabilities or the end quality of our parts.

Precision

Many manufacturers will cut corners to save on costs. Selecting an experienced stamping supplier is key to avoiding operational inefficiencies and achieving long-term project success. With our decades of experience and state-of-the-art equipment, we know how to correctly achieve the highest levels of precision at the most affordable cost.

Consistency

Utilizing tools like computer-aided design (CAD), proper tooling, and quality control can help ensure the uniformity of every piece and part that’s produced. At Keats, we regularly perform CPK studies on all our processes. This is how we achieve industry leading levels of process stability and repeatability.

Mass Production

We have the proper machinery, tooling, and experience to manage large orders quickly and efficiently. Our focus lies primarily on high-volume projects, making our capabilities are ideal for large appliance production runs.

Raw Material Utilization and Cost

Keats makes strides to examine and remove waste from every possible aspect of our production process to help keep costs low. Our tooling and engineering teams also utilize production methods developed to optimize the use of raw materials. This allows us to offer more competitive pricing than most other suppliers.

Common Appliance Industry Applications

Stamped metal components find their way into nearly every domestic and commercial appliance, including:

- Stoves

- Ovens

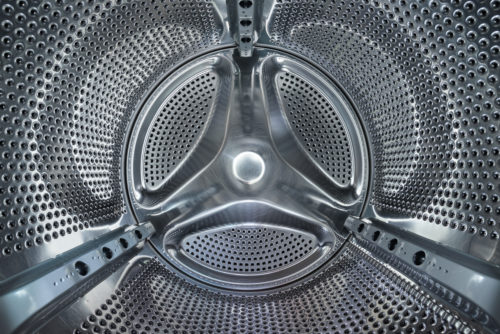

- Washers

- Dryers

- Dishwashers

- Garbage disposals

- Refrigerators

- Grills

- Automatic garage doors

- Security systems

- Thermostats

- Water heaters

- HVAC units

- Irrigation systems

- Pool filtration systems and pumps

Custom Stamped Metal Components

Our decades of experience allow us to work with virtually any project geared towards any industry. We also offer unlimited RoHS-compliant plating resources such as zinc, nickel, and tin and other finish options such as dip-and-spin and black oxide. Some examples of custom stamped metal components include:

- Assemblies (including multistage tooling to avoid secondary processes)

- Brackets

- Clips made from annealed spring steel and heat-treated to custom HRC requirements using austempering, vacuum hardening, and oil quench processes

- Bushings and brackets (instrument panels, door panels, etc.)

- Lead frames (electronics, microchip management)

- Shields

- Heat sinks

- Terminals (pre-post, selective, precious metal plating)

- Wire forms (fasteners, links, springs, rings, hooks, terminals)

Keats Manufacturing provides customers with the highest-quality custom metal stamped parts, wire forms, and assemblies on the market. Our facilities are certified to the following standards:

- ISO 9001

- IATF 16949

- ISO 14001

We collect data at each and every step of the manufacturing process and follow up with final inspection before every delivery to ensure the best possible part quality. No matter how complex the job, clients can rest assured that all final products will meet their exact specifications.