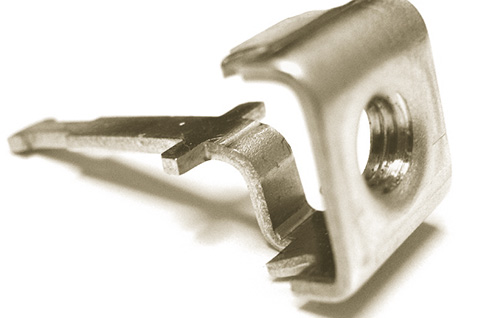

Keats was approached by an electrical industry client to multi-slide stamp and screw thread tap brass terminals.

We first designed the .040″ thick, 1.925″ long and .405″ wide contacts using AutoCAD software. Then, we multi-slide stamped the 750,000 terminals, all while holding tightest tolerances of ±.001″ throughout the process. Keats utilized an in-line screw thread tapping process. 10,000+ of the 260 brass terminals were delivered weekly to the Mexico-based client.

For more information about this multi-slide stamp project, please see the details below. To learn all about our other services please contact Keats.

Project Highlights for a Multi-Slide Stamping with Screw Thread Tapping

Product Description

These brass terminals are used within an electrical power distribution application.

Capabilities Applied/Processes

Primary:

Design

-Design Contact Using AutoCAD

Multi-Slide Stamping

Overall Part Dimensions

Material Thickness: .040"

Length: 1.925"

Width: .405"

Tightest Tolerances

±.001"

Material Used

260 Brass

Industry for Use

Electrical

Volume

750,000 Annual

Delivery Time

15,000 Per Week

Delivery Location

Mexico

Standards Met

Customer supplied print, 2D CAD Drawing

Product Name

Terminal