Metal Stamping in the Automotive Sector

Leave a CommentAutomobiles rely on a wide range of components to operate safely and efficiently. Most of these components — which are found in every part of a vehicle, from its frame to its electrical systems — are manufactured using metal stamping and precision machining methods.

Metal stamping, also referred to as pressing, involves placing a sheet or coil of metal into a press and forming it into the desired shape over a die or mold. This can be done in one stage or over several stages, depending on the complexity of the required end product.

Automotive stamping allows for the manufacture of many different functioning parts, which are used in automotive bodies and frames, as well as electrical, steering, alternator, and fuel systems. These components play a crucial role in ensuring optimal safety and functionality.

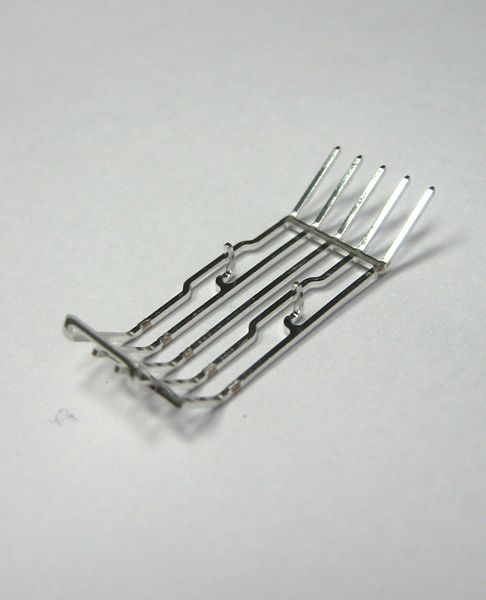

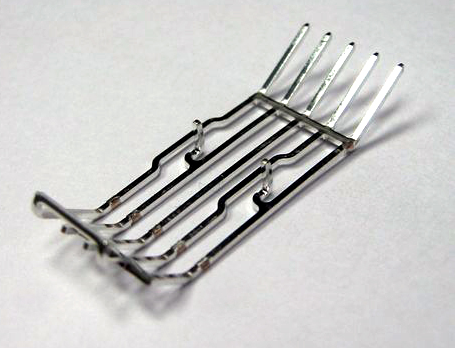

Terminals and Electrical Connectors

The auto industry produces thousands of vehicles a year, and hundreds of terminals and electrical connectors are installed in each vehicle.

Automotive manufacturers typically employ connectors with a two-piece socket and tab design. Using flexible materials, the male and female component ends can easily attach and disconnect, allowing for great durability and flexibility. This is crucial, given the amount of abuse these components take from weather, general wear and tear, chemical exposure, and other harsh elements cars encounter on the road.

As the auto industry depends more and more on electrical systems, demand will rise for highly protected, durable terminals and connectors. These components can be made from a variety of different materials — including copper, brass, phosphor bronze, and various grades of steel — using four/multi-slide forming and progressive die and metal stamping techniques.

Automotive Wire Forms

The wire forming process involves pulling a strip of metal through a series of lubricated metal dies or molds so it can take the desired shape. Allowing for many wire sizes and shapes, this simple, versatile process can even be applied to glass. Commonly worked materials include titanium and copper, but the ideal material choice will depend on the specific application at hand.

Wire formed products are used in a wide range of applications, including construction, which makes use of rebar, as well as heating elements and even mattresses, which make use of springs and coils. In the auto industry, wire formed products are found in tires and under chassis.

Automotive Brackets and Hangers

Metal brackets are also found in many different automotive applications — door panels, instrument panels, fender assemblies, and airbags, to name just a few. Primarily used to fasten one component to another, brackets can be manufactured from metals such as steel, as well as various other high-strength, oxidation-resistant alloys. Since automotive brackets may be exposed to the elements, these properties are particularly important.

Learn More about Automotive Stamping

Metal stamping and precision machining techniques are essential for ensuring optimal safety, reliability, and comfort in all types of vehicles. These processes, whether complex or simple, require experienced and dedicated technicians; companies should be sure to partner with knowledgeable industry leaders who can provide reliable solutions tailored to the specific application at hand. Components must be durable enough to withstand years of use in varying road and weather conditions, so quality is of utmost importance.

At Keats Manufacturing Co., we’re proud to offer industry-leading wire form design and manufacturing services. Committed to quality in everything we do, our facilities are ISO 9001, ISO 14001 and TS 16949 compliant, and we make use of the latest technological innovations, including CAD/CAM. Our operations are overseen by 25 of the industry’s most experienced die makers.

For more information on our custom metal stamping services for the automotive industry and discuss automotive component manufacturing options for your unique application, reach out to the team today.

An automotive manufacturer provided Keats with a print and a .DWG AutoCAD file that contained specifications of a fuel injection steel shield that was required for use in automotive engines.

An automotive manufacturer provided Keats with a print and a .DWG AutoCAD file that contained specifications of a fuel injection steel shield that was required for use in automotive engines. One client came to Keats with a need for terminals to be used in sensors for various automotive parts. Starting with copper alloy wires with a thickness of 0.082”, the Keats engineering team leveraged our in-house AutoCAD and tooling machinery to achieve tolerances of 0.001” to manufacture 25,000 terminal

One client came to Keats with a need for terminals to be used in sensors for various automotive parts. Starting with copper alloy wires with a thickness of 0.082”, the Keats engineering team leveraged our in-house AutoCAD and tooling machinery to achieve tolerances of 0.001” to manufacture 25,000 terminal  What are electrical contacts and terminals?

What are electrical contacts and terminals? Commonly used materials for auto industry

Commonly used materials for auto industry  Creating reels of close tolerance terminals and contacts requires advanced stamping techniques. We employ progressive die and four-slide/multi-slide stamping to manufacture enormous volumes of high-precision components (sometimes 20 million or more parts) with the industry’s closest tolerances, including down to ± .001”.

Creating reels of close tolerance terminals and contacts requires advanced stamping techniques. We employ progressive die and four-slide/multi-slide stamping to manufacture enormous volumes of high-precision components (sometimes 20 million or more parts) with the industry’s closest tolerances, including down to ± .001”. Highly efficient and cost effective,

Highly efficient and cost effective,