Material Matters: Choosing the Right Metal for Your Project

The dedicated team at Keats Manufacturing Co. has been crafting stamped metal parts since 1958. Over the past few decades, we’ve seen a number of unique projects and individual parts come through our facility. While many decisions — from design details to custom tooling — influence these parts’ performance, one of the first choices made in the manufacturing process is always the most critical: material.

Common Materials, Uncommon Quality

Every metal comes with its own benefits and weaknesses, and these properties lend each material to different ideal uses.  Achieving the best results for a stamping project is always the result of carefully researching and choosing a part’s optimal material fit.

Achieving the best results for a stamping project is always the result of carefully researching and choosing a part’s optimal material fit.

At Keats Manufacturing Co., we pride ourselves on offering the highest quality products, from common steel components to custom crafted specialized alloy parts. Here are our top five material choices for custom stamping projects.

Copper

Copper offers some of the best available conductivity (100%), behind only silver and gold in its performance.  Copper is also known for its corrosion resistance to industrial atmospheres, water, non-oxidizing acids, alkalis, and neutral saline solutions. While it doesn’t react with water, copper gradually forms a brownish-black oxide when exposed to atmospheric oxygen. Unlike rust, this oxide will actually protect the copper underneath from further corrosion.

Copper is also known for its corrosion resistance to industrial atmospheres, water, non-oxidizing acids, alkalis, and neutral saline solutions. While it doesn’t react with water, copper gradually forms a brownish-black oxide when exposed to atmospheric oxygen. Unlike rust, this oxide will actually protect the copper underneath from further corrosion.

Copper is very malleable, ductile, and responsive to precision tooling. For automotive and electrical stamped part applications, it is best used at 0.010” – 0.050” thickness.

Copper alloys commonly used at Keats are: C102, C110, C122, C194 & C197.

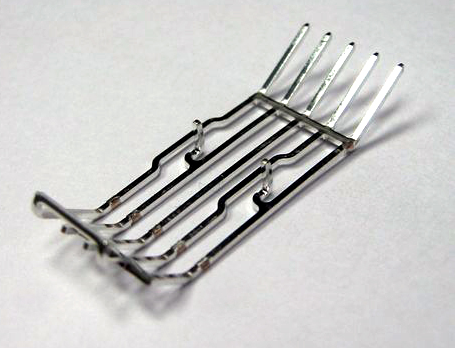

Our copper part highlights include reel to reel terminals, loose terminals, conductive lead frames, grids, wire forms, clips, antennas, and prototype and short-run parts. Our custom metal stamping portfolio also includes beryllium copper springs for use in hearing aid applications.

Phosphor Bronze

A specialized alloy of copper, phosphor bronze contains up to 10% tin and up to 1% phosphorous, which provides deoxidizing during melting. While phosphor bronze lacks copper’s extreme conductivity (only 15%), it allows for electrical connections to devices at ultra-low temperatures due to its fair electrical performance combined with very low thermal conduction.

Phosphor Bronze is also insensitive to stress corrosion cracking and offers good corrosion resistance to sea water and industrial atmospheres. Known for its toughness, strength, and low coefficient of friction, phosphor bronze is a popular choice for springs, bolts, and heavy fatigue applications. It is best used at 0.008” – 0.050” thickness for automotive and electrical applications.

Phosphor Bronze is also insensitive to stress corrosion cracking and offers good corrosion resistance to sea water and industrial atmospheres. Known for its toughness, strength, and low coefficient of friction, phosphor bronze is a popular choice for springs, bolts, and heavy fatigue applications. It is best used at 0.008” – 0.050” thickness for automotive and electrical applications.

Phosphor Bronze alloys commonly used at Keats are: C510, C511, C519 & C521.

Our bronze stamping portfolio includes reel to reel terminals, contacts, loose terminals, conductive lead frames, grids, and prototype and short-run parts.

Brass

Often the most cost effective choice for electrical applications because of its lower price point than pure copper, brass is known for its malleability, hardness, and resistance to corrosion, not to mention its pleasing appearance. Made by blending copper and zinc, it offers higher malleability than bronze or zinc alone. Nearly 90% of its alloys are, in fact, a result of these materials being recycled!

Brass offers good resistance to fresh water, neutral or alkaline saline solution, organic compounds, and standard atmospheres at sea, on land, and in manufacturing. Adding aluminum to a brass alloy can strengthen its given corrosion resistance, while adding lead can enhance its machinability.

Brass offers good resistance to fresh water, neutral or alkaline saline solution, organic compounds, and standard atmospheres at sea, on land, and in manufacturing. Adding aluminum to a brass alloy can strengthen its given corrosion resistance, while adding lead can enhance its machinability.

With a solid conductivity of 28%, brass is common in automotive and electrical applications at thicknesses up to 0.050”.

Brass alloys commonly used at Keats are: C210, C220, C230, C260, C268 & C272.

Our brass part highlights include reel to reel terminals and contacts, loose terminals, contacts, conductive lead frames, grids, brush guards and holders, and prototype and short-run parts.

Aluminum

An extremely popular material choice, aluminum is likely best known for its exceptional strength-to-weight ratio, making it ideal for strong, lightweight parts, both on its own and in combination with other metals.

Aluminum is also known for its corrosion resistance — it is tolerant to moisture and most chemicals — as well as its low density. The metal offers 61% conductivity and is capable of thermal and electrical superconductivity, as well.

Aluminum is also known for its corrosion resistance — it is tolerant to moisture and most chemicals — as well as its low density. The metal offers 61% conductivity and is capable of thermal and electrical superconductivity, as well.

Soft, durable, lightweight, ductile, and malleable, aluminum is popular for automotive and mechanical components at thicknesses ranging from 0.012” to 0.120”.

Aluminum alloys commonly used at Keats are: 3003, 1100, 5056, 5052 & 5154.

Our aluminum part highlights include clips, clamps and flat springs, brackets, latches, covers, wire forms, antennas, and prototype and short-run parts.

Steel

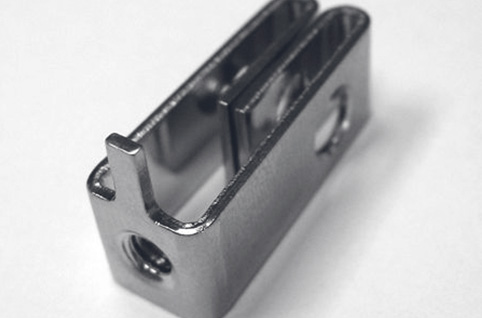

Annealed, cold-rolled, stainless — there are countless steel alloys designed to suit any industry. A classic combination of iron with carbon and any number of other elements, steel is created by reducing the carbon in iron ore and replacing it with materials to alter traits such as strength, conductivity, and corrosion resistance. In addition, heat treating processes such as annealing, quenching, and tempering can alter the material and its end performance.

Steel is typically resistant to corrosion with a wide conductivity range (up to 15%) and great formability and durability. A low cost option, it presents good baseline tensile and yield strength. However, all of these properties can vary greatly, offering a wide array of choices to create the perfect fit for a particular project. Annealed steel, for example, is far more ductile and fracture-resistant than its counterpart prior to heat treatment, and G1050 is an alloy specifically created for versatility and machinability in engineering applications.

Material Guidance with Keats Manufacturing Co.

With over 50 years of excellence in custom fabrication and small metal parts, the Keats Manufacturing Co. team knows a thing or two about material choices and manufacturing.

To learn more about how solid research and great materials can benefit your next project, download our eBook, 10 Ways to Reduce Turnaround Time and Cost of a Metal Stamped Part, or reach out and contact us today.

To learn more about how solid research and great materials can benefit your next project, download our eBook, 10 Ways to Reduce Turnaround Time and Cost of a Metal Stamped Part, or reach out and contact us today.