For over six decades, Keats Manufacturing has crafted high-quality custom metal stampings and assemblies. Our product offerings include custom metal brackets, which are manufactured in adherence to even the most stringent application requirements. Our custom metal bracket capabilities include various design options, materials, finishes, and more to meet the needs of several applications.

Overview

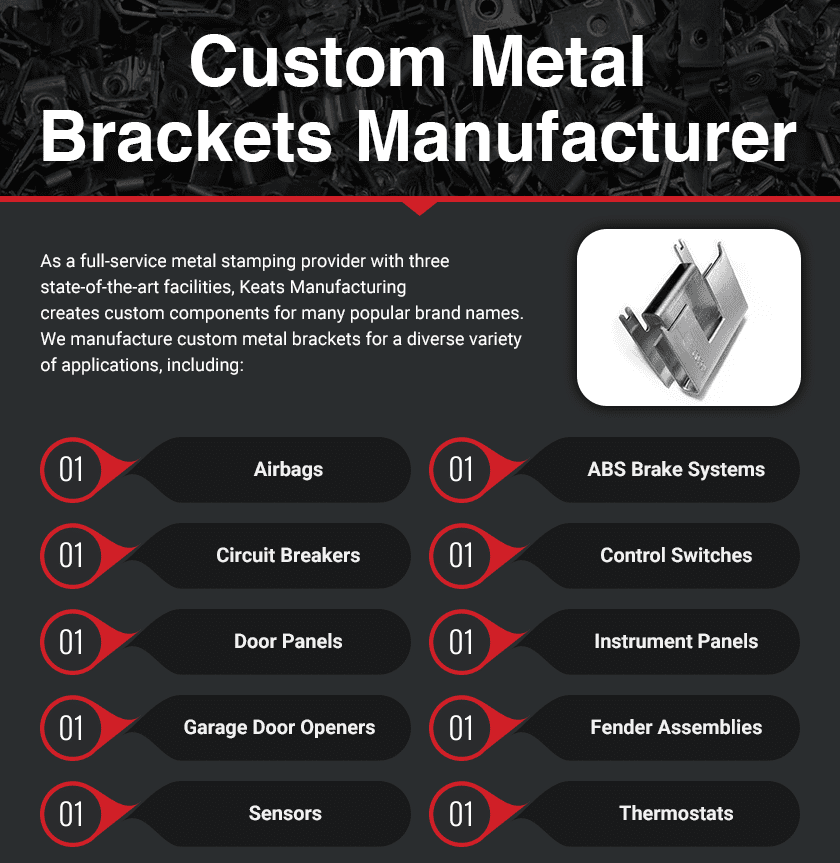

As a full-service metal stamping provider with three state-of-the-art facilities, Keats Manufacturing creates custom components for many popular brand names. We manufacture custom metal brackets for a diverse variety of applications, including:

- Airbags

- ABS brake systems

- Circuit breakers

- Control switches

- Door panels

- Instrument panels

- Garage door openers

- Fender assemblies

- Sensors

- Thermostats

We are dedicated to providing our customers with products and services of unmatched quality. Our high standards and attention to detail differentiate our products from the competition. All Keats Manufacturing facilities are ISO:14001, ISO:9001, and TS:16949 certified and use the most cutting-edge technology, including EDM, CAD/CAM, and CNC machines. Our operations are overseen by 25 of the industry’s most experienced die makers, whose quality control protocols ensure all final products adhere to our customers’ high standards.

Materials

At Keats Manufacturing, we work with a wide variety of metals to meet the needs of diverse projects. Our custom metal brackets are made from steel, aluminum, and stainless steel.

Steel Brackets

Steel typically needs to be painted to prevent rust and corrosion. It features many beneficial characteristics, such as:

- Less expensive than aluminum

- Highly durable and resilient

- High tensile strength

Aluminum Brackets

Aluminum is lightweight as well as highly malleable and ductile. Aluminum brackets are:

- Low density

- Non-magnetic

- Low tensile strength

- Non-ferrous (not containing iron)

Stainless Steel Brackets

Offered in a variety of grades, stainless steel is highly durable, heat resistant, and requires little maintenance. Brackets made from stainless steel feature qualities that include:

- A minimum of 11% chromium

- Ferrous (containing iron)

- Typically magnetic

- High tensile strength

Capabilities

Custom metal brackets from Keats Manufacturing are enhanced by a range of plating and coating services, as well as prototyping, design, and assembly capabilities.

RoHS Compliance

Our brackets meet or exceed the European Union’s Directive 2002/95/EC requirements on the restriction of hazardous substances.

Barrel and Rack Plating

These electroplating processes coat metal components with a protective finish designed to prevent rust, corrosion, and embrittlement. We offer the following processes:

- Barrel-plated brackets. During this process, brackets are placed in a polypropylene barrel that features center bars to conduct electricity. The brackets tumble in the barrel, creating a smooth finish that is functional as well as aesthetically appealing.

- Shelf/Rack Plated Brackets. Shelf plating, or rack plating, involves placing the brackets into a machine where they are held stationary rather than tumbling. This process is reserved for fragile or complex designs.

Four Slide

Keats Manufacturing is an industry leader in four-slide technology and has the largest fleet of four-slide machines of any supplier. Since four-slide equipment eliminates the need for a carrier strip, as much as 35% of material costs can be saved using this manufacturing method.

Progressive Die Stamping

Brackets that cannot be produced using a four-slide machine are best produced using progressive die stamping. Each of our facilities features a large fleet of stamping presses, all utilizing the latest die design technology. Our equipment features servo feed units and sensors to ensure the highest level of efficiency possible.

Just-In-Time Delivery

Our order fulfillment processes are streamlined using inventory management solutions that include EDI and KANBAN.

Design and Assembly

In addition to manufacturing existing designs, our team also develops custom bracket component designs and assembles multi-part bracket assemblies.

Prototyping Services

For new or customized projects, we develop prototypes and samples for testing. We refine bracket designs to create components ideally suited to high-volume orders.

Custom Metal Brackets From Keats Manufacturing

Keats Manufacturing serves the biggest names in the automotive, appliance, and electrical distribution industries. As an ITAF and ISO 9001-certified company, our clients can be confident in the safety and quality of the components we produce. We use the top metalworking techniques alongside state-of-the-art equipment to deliver products of unmatched quality.

Our metal brackets are available in a wide variety of preexisting, standard designs, or we can develop a custom configuration of any size, metal, and design complexity. We handle high-volume orders of up to 50 million parts, providing ongoing customer support and just-in-time delivery services. Contact us today with any questions or request a quote for your next bracket project.