Simple but powerful, bus bars play critical roles in a variety of electrical systems. Electrical bus bars collect, control, and distribute the flow of current through an electrical delivery system. They enable power to be gathered and distributed efficiently and safely. Learn more about bus bars, including their benefits, common applications, and how Keats Manufacturing can support your bus bar stamping needs.

Bus Bars Explained

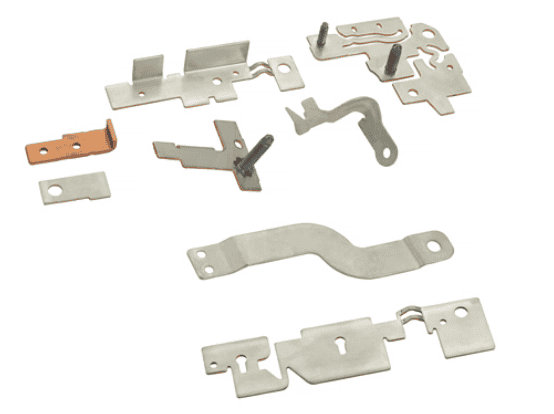

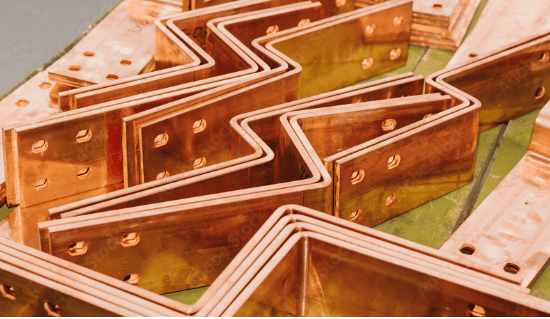

At their most basic level, bus bars collect input currents and distribute them to output circuits. As a junction between input and output power, bus bars are made up of stamped conductive material, usually copper or aluminum. Depending on the electrical type, bus bars can reduce maintenance, labor, and installation costs. Because they are fast and easy to connect and install, bus bars are used in a wide range of settings, such as:

- Data centers

- Automobiles (ICE & EV)

- Hospitals

- Computer systems

- Railways

- Metro systems

- Public institutions

- Industrial facilities

Usually 0.050” to 0.250” in thickness, bus bars feature a circuit breaker and isolator. In the event of a fault, the circuit breaker is triggered, and that area of the bus bar can be safely disconnected so that it can be serviced. The most common type of bus bar in electrical power distribution is rectangular.

The ability of rigid stamped bus bars to consolidate power streamlines complex electrical setups, making them indispensable in industries requiring reliable and efficient power delivery, such as:

- Automotive: Bus bars are central to power distribution, channeling electricity throughout traditional ICE vehicles, PHEVs, HEVs, and EVs.

- Transportation: They’re also integral to broader transportation systems, including electric trains, trams, railways, and metro systems, helping power reach all necessary components.

- Electrical switchgear and panels: Bus bars serve as the primary power distribution point for electrical panels and control systems.

- Defense equipment: For military applications, bus bars are essential in systems like communications, power generation, and weapons, facilitating efficient electrical power flow in demanding environments.

Advantages of Stamped Rigid Bus Bars

- Enhanced design versatility: Bus bars offer a variety of interconnection styles to fit any interface.

- Lower stray circuit inductance: Bus bar assemblies can be fabricated to minimize stray circuit inductance.

- Increased efficiency: They enable all required connections between components while increasing efficiency.

- Improved reliability: Bus bars reduce the risk of wiring errors and points of failure.

- Increased capacitance: Bus bars have more capacitance, which helps suppress noise.

- Lowered costs: Because they use fewer materials and simplify installation and maintenance, bus bars help lower overall costs.

- Heat dissipation: Designed for optimal airflow, bus bars can also serve as heat sinks.

Aluminum and copper bus bars offer a variety of key advantages, including:

- Simplified distribution: Stamped bus bars consolidate power and simplify intricate networks. Their compact design saves valuable space in tight or populated areas.

- Cost effectiveness: Replacing multiple individual conductors, rigid stamped bus bars reduce material use and installation labor. This leads to substantial savings for high-volume production.

- Enhanced protection: Many bus bar systems integrate protective devices, safeguarding against faults and overloads and improving overall system safety and reliability.

- Flexibility: Stamped bus bars easily adjust to varying power requirements. You can add or remove feeders or extend the system to new sections based on custom configurations.

- Easy maintenance: Designed for convenient access, bus bars simplify maintenance, reducing downtime and operational costs.

- Supply continuity & fault isolation: Certain bus bar arrangements maintain power during maintenance or faults. Designs like ring mains isolate faults to specific segments, drastically reducing downtime and promoting continuous operation.

- Environmental sustainability: Both copper and aluminum bus bars are recyclable, offering an environmentally conscious choice.

Choosing Keats for Your Bus Bar Needs

Producing the highest-quality bus bars, Keats Manufacturing is ISO 9001, ISO 14001, and IATF 16949 certified. Our adherence to stringent quality controls delivers customer satisfaction and product confidence. Regardless of order size or complexity, our team has the skills, facilities, and certifications to provide superior product quality every time at an affordable price. We specialize in custom stamped bus bars tailored to your exact specifications.

Keats Manufacturing’s bus bar fabrication processes are designed to provide maximum quality while minimizing scrap waste and costs. As experts in strip layouts, our engineers know how to design and fabricate stamped bus bars in the most material-efficient, cost-effective ways. Bus bar materials and options we work with include:

- Heavy-gauge copper and aluminum

- Pre- or post-plating options for enhanced corrosion protection

- Selective pre- or post-plating

To produce our bus bars, we use progressive die-stamping technology and equipment that can accommodate:

- 60 to 250 tons of die stamping pressure

- Tooling transferred or staged according to the geometry of your part

- Strip widths equal to part widths, minimizing scrap per strip

- Large coil handling capabilities

- Hand-stacked packaging and custom cell packing to protect parts from scratches, if required

Quality Bus Bars From Keats Manufacturing

When you choose stamped bus bars from Keats Manufacturing, you gain a high-quality, affordable solution for your electrical distribution needs. Whether they’re for transportation systems, electrical panels, or power distribution, we provide precision bus bar components and assemblies to reduce system complexity, minimize downtime, and lower maintenance costs. Contact us today to learn more about our products and services, or request a quote for your project.