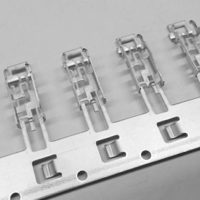

Meeting ultra-tight tolerances down to ±.005″, Keats Manufacturing Co. designed and built these reel to reel phosphor bronze terminals for use in automotive lighting applications.

Keats’ engineers employed AutoCAD software to design the custom tooling for these parts. We then formed and stamped the coil stock to print from .014 ASTM B103 #510 phosphor bronze material.

After successfully fulfilling customer expectations for both design and quality, Keats Manufacturing Co. continues to manufacture up to 850,000 of these terminals annually for this client. Furthermore, our Kanban software program ensures Just-in-Time delivery of these parts to our buyer’s facility in Indiana.

For additional information on this portfolio, please refer to the table below. We also encourage you to check out our eBook, Design Tips for Automotive Contacts & Terminals.

Reel to Reel Phosphor Bronze Terminals

Product Description

Reel to Reel Phosphor Bronze Terminals used in an Automotive Application

Capabilities Applied/Processes

Formed and Stamped Coil Stock

Tightest Tolerance

±.005"

Material Thickness

.014"

Material Applied

ASTM B103 #510 Phosphor Bronze

Industry for Use

Automotive Lighting

Volume

850,000/yr

Delivery Time

Kanban

Delivery Location

Indiana and Mexico

Standards Met

Customer Supplied Print, DWG AutoCAD File

Product Name

Terminal

Project Scope

Design and Build Terminal for Automotive Application

Design Work

AutoCAD Design Software to Design Tooling