Metal bushings, also known as torque limiters, are cylindrical components that improve efficiency and minimize noise and vibration in equipment with rotating or sliding shafts. They ensure smooth operation in a range of high-impact, high-load applications, from heavy-duty agricultural equipment to automotive mechanical assemblies. For optimal performance, metal bushings require accurate design specifications, careful material selection, and precision machining or stamping techniques.

What are Metal Bushings?

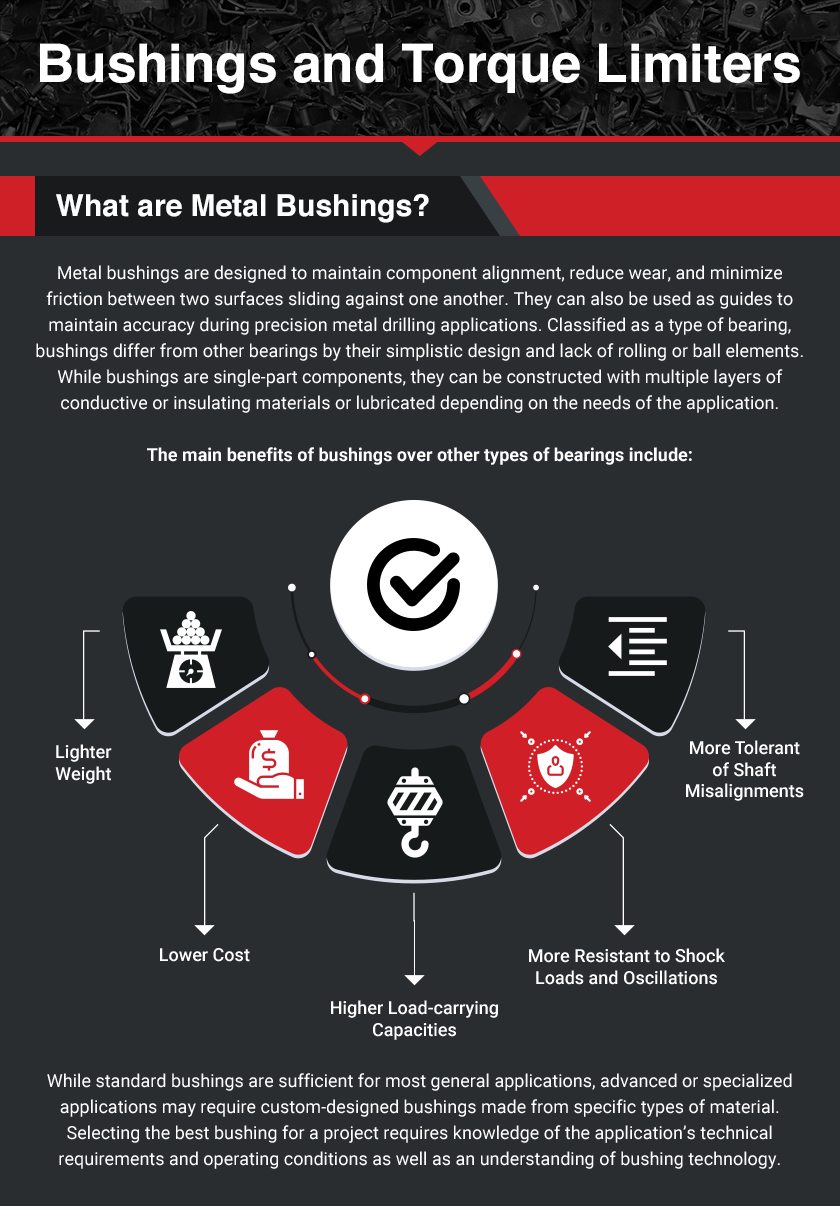

Metal bushings are designed to maintain component alignment, reduce wear, and minimize friction between two surfaces sliding against one another. They can also be used as guides to maintain accuracy during precision metal drilling applications. Classified as a type of bearing, bushings differ from other bearings by their simplistic design and lack of rolling or ball elements. While bushings are single-part components, they can be constructed with multiple layers of conductive or insulating materials or lubricated depending on the needs of the application.

The main benefits of bushings over other types of bearings include:

- Lighter weight

- Lower cost

- Higher load-carrying capacities

- More resistant to shock loads and oscillations

- More tolerant of shaft misalignments

While standard bushings are sufficient for most general applications, advanced or specialized applications may require custom-designed bushings made from specific types of material. Selecting the best bushing for a project requires knowledge of the application’s technical requirements and operating conditions as well as an understanding of bushing technology.

Bushing Applications

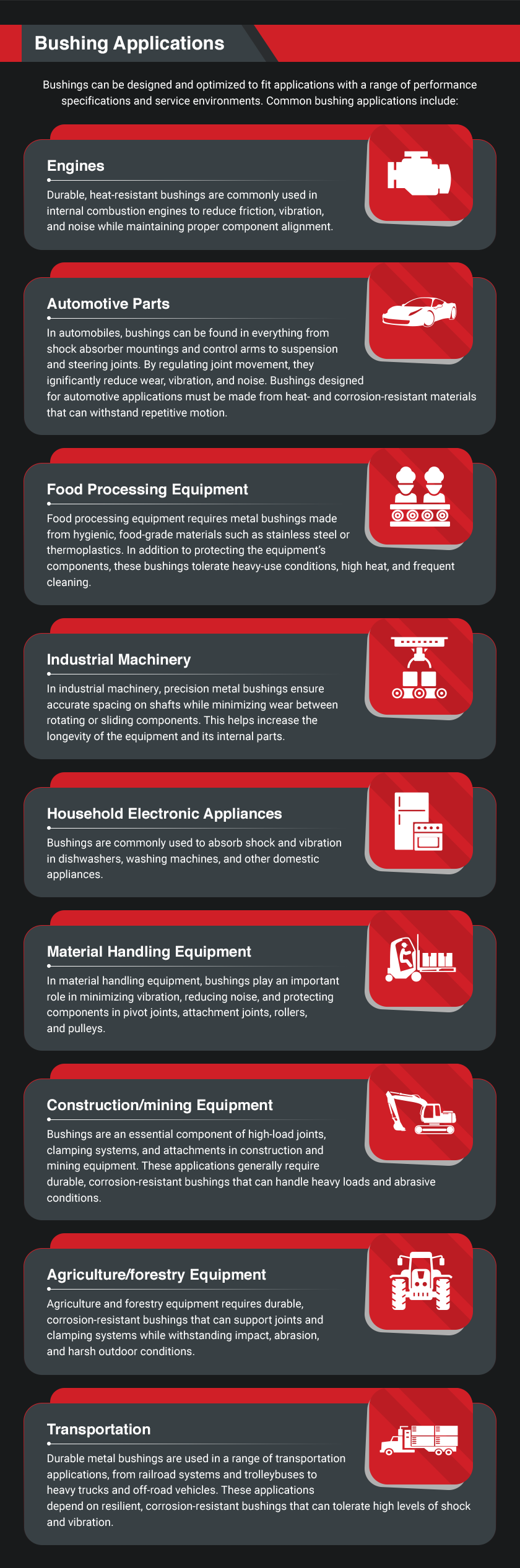

Bushings can be designed and optimized to fit applications with a range of performance specifications and service environments. Common bushing applications include:

- Engines: Durable, heat-resistant bushings are commonly used in internal combustion engines to reduce friction, vibration, and noise while maintaining proper component alignment.

- Automotive parts: In automobiles, bushings can be found in everything from shock absorber mountings and control arms to suspension and steering joints. By regulating joint movement, they significantly reduce wear, vibration, and noise. Bushings designed for automotive applications must be made from heat- and corrosion-resistant materials that can withstand repetitive motion.

- Food processing equipment: Food processing equipment requires metal bushings made from hygienic, food-grade materials such as stainless steel or thermoplastics. In addition to protecting the equipment’s components, these bushings tolerate heavy-use conditions, high heat, and frequent cleaning.

- Industrial machinery: In industrial machinery, precision metal bushings ensure accurate spacing on shafts while minimizing wear between rotating or sliding components. This helps increase the longevity of the equipment and its internal parts.

- Household electronic appliances: Bushings are commonly used to absorb shock and vibration in dishwashers, washing machines, and other domestic appliances.

- Material handling equipment: In material handling equipment, bushings play an important role in minimizing vibration, reducing noise, and protecting components in pivot joints, attachment joints, rollers, and pulleys.

- Construction/mining equipment: Bushings are an essential component of high-load joints, clamping systems, and attachments in construction and mining equipment. These applications generally require durable, corrosion-resistant bushings that can handle heavy loads and abrasive conditions.

- Agriculture/forestry equipment: Agriculture and forestry equipment requires durable, corrosion-resistant bushings that can support joints and clamping systems while withstanding impact, abrasion, and harsh outdoor conditions.

- Transportation: Durable metal bushings are used in a range of transportation applications, from railroad systems and trolleybuses to heavy trucks and off-road vehicles. These applications depend on resilient, corrosion-resistant bushings that can tolerate high levels of shock and vibration.

Bushing Materials

Metal bushings can be made from a range of cast or machined metals and alloys. The chosen material should be capable of protecting the rotating or sliding components from damage while withstanding the specific conditions of use. Two common metal bushing materials include:

- Steel: Steel is a high-strength iron-carbon alloy with a carbon content ranging from 0.002–2.1%. Bushings made from steel offer exceptional fatigue resistance, corrosion resistance, and surface behavior. These attributes make them a long-lasting and reliable solution for high-load, high-impact applications involving extreme temperatures or corrosive conditions. They also guide drill jigs and other machining operations.

- Aluminum: Known for its excellent strength-to-weight ratio, aluminum is commonly used to produce lightweight bushings used in light-duty, low-speed applications. Aluminum can also be alloyed with other metals to create bushings with specific material properties for certain applications. For example, aluminum bronze bushings combine the benefits of bronze and aluminum to provide excellent tensile strength, ductility, weldability, and fatigue resistance. They also offer great corrosion resistance, making them ideal for various moisture-rich environments.

Why Keats Manufacturing?

At Keats Manufacturing, we provide standard and custom bushings made from high-quality metals, alloys, and composite materials. Capabilities and certifications that distinguish us from our competitors include:

- State-of-the-art technology: Using four-slide/multi-slide stamping press technology, we form and shape high volumes of metal parts with exceptional accuracy and efficiency. This process is ideal for the cost-effective production of small, high-precision metal components such as bushings. We also utilize CAD/CAM software, EDM techniques, and state-of-the-art CNC machines to make sure each product meets exact customer specifications.

- In-house tooling & dies: With our in-house tooling and die-making capabilities, customers can easily and quickly modify designs without increased wait times or added costs. Having complete control over the tooling process also allows us to provide shorter turn-around times and higher-quality parts.

- ISO-certified facilities: To better serve our customers, we utilize three full-service facilities that are each certified to ISO 9001, ISO 14001, and TSI 16949 standards.

- Cost-effective production: With efficient metal forming techniques such as four-slide stamping, we can facilitate high-volume orders while keeping production expenses low.

- Just-in-time delivery: Our efficient MRP system allows us to accurately align with our customer’s production schedules to provide everything from custom labeling to digitally updated stock levels as close to the time they are needed.

Custom Metal Bushings at Keats Manufacturing

Metal-stamped bushings play a key role in reducing friction and keeping components accurately aligned in equipment with moving parts. At Keats Manufacturing, we understand the importance of well-designed, accurately fitting bushings when it comes to maximizing longevity and efficiency in your application. We work with customers from a range of industries to provide high-quality metal-stamped bushings that are customized to exact specifications.

To learn more about our custom metal bushings and other products, please contact us today or request a quote.