View our case studies to see how we have continuously provided our customers with the highest quality of products, quickly and at an economical price.

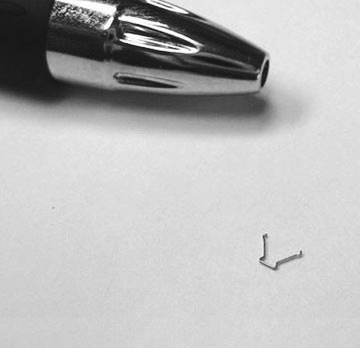

Beryllium Copper Spring-Contact Stamping for Hearing Aid ApplicationThe beryllium copper spring contact was manufactured by Keats Manufacturing Company for a large medical component manufacturer in Minnesota. These spring contacts were used in hearing aid applications.Learn More

Hearing Aid Application

Beryllium Copper Spring Contact Stamping

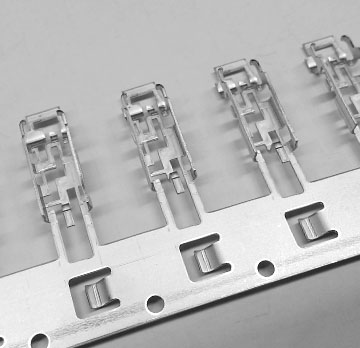

Copper Top Spring Stamping & Contact Assembly for Appliance ApplicationWe manufactured and assembled the contact assembly seen in the image for use in appliance timer controls. AutoCAD software was used to design the automated assembly for terminals, blades and contacts.Learn More

Apppliance Application

Copper Top Spring Stamp-ing & Contact Assembly

Phosphor Bronze Terminal Stamping for Automotive ApplicationThe terminal seen in the picture was manufactured for automotive steering position sensors from a 0.0238” thick phosphor bronze material.Learn More

Automotive Application

Phosphor Bronze Terminal Stamping

Steel Shield Four Slide, Multi-Slide Stamping for Automotive ApplicationWe designed and built this fuel injection steel shield for use in automotive engines. This shield was manufactured from 1008 / 1010 cold rolled steel.Learn More

Automotive Application

Steel Shield Four Slide, Multi-Slide Stamping

Reel to Reel Phosphor Bronze Terminals Used in Automotive ApplicationMeeting ultra-tight tolerances down to ±.005″, Keats Manufacturing Co. designed and built these reel to reel phosphor bronze terminals for use in automotive lighting applications.Learn More

Automotive Application

Brass Formed Hinged Contact Jaw

Brass Formed Hinged Contact Jaw for Electrical BoxWe produced 1 million pieces of this hinged contact jaw using the multi-slide stamping process. Tooling for the stamping process was designed using AUTOCAD.Learn More