Custom Assemblies

Keats Manufacturing specializes in the design of manufacturing tools and processes to deliver high-quality custom metal assemblies that meet the precise specifications of aerospace, appliance, automotive, and general manufacturing industries.

We combine decades of experience with cutting-edge advanced technologies such as EDM, CAD/CAM, and CNC machines to meet our customers’ unique requirements. Our unsurpassed quality assurance processes ensure our custom assemblies adhere to rigorous industry standards. Our facilities are IATF:16949, ISO:14001, and ISO:9001 certified to ensure our customers receive the best quality and service. Our new state-of-the-art manufacturing facility in Queretaro, Mexico, also allows us to perform manual, complex, multi-stage assembly processes at a competitive price.

At Keats Manufacturing, we offer the following assembly processes:

- Part threading and screw insertion

- Silver and copper contact staking

- Press-fit bolt insertion

- In-line part-to-part assembly

- Kitting and bagging

These processes are optimized for long-term reliability and process stability. We offer just-in-time delivery (JIT) for all our custom metal products, leveraging advanced multi-stage tooling that eliminates the need for secondary processing steps to reduce costs. We also partner with automation experts to enhance efficiency and develop reliable custom equipment that meets our customers’ specific assembly requirements.

Custom Brackets

Custom brackets are utilized across a broad range of industries, and Keats Manufacturing has the knowledge and expertise to deliver high-quality products that match the exact specifications required by our customers. Our custom bracket manufacturing processes deliver reliable components that meet the demands of a wide variety of products and applications, such as:

- Aerospace systems

- Airbags

- Anti-lock brake systems

- Automotive door panels

- Control switches

- Fender assemblies

- Instrument panels

Utilizing CAD technology allows us to design specialized tooling configurations to ensure precise production. We provide full design and assembly services along with JIT delivery of our custom brackets, and we can seamlessly integrate the following plating techniques to enhance durability and surface protection:

- Barrel

- Dip-spin

- E-coat

- Rack

- Selective precious metal reel-to-reel

All of the brackets we supply adhere to regulatory and environmental standards, including the Restriction of Hazardous Substances Directive (RoHS).

Custom Electrical Terminals

At Keats Manufacturing, we focus on delivering exceptional durability and conductivity, developing high-quality manufacturing processes for electrical terminals used in the following sectors:

- Aerospace

- Appliance

- Automotive

- Communications

- Construction

- Electrical

- General manufacturing

- Machining

- Medical/medical devices

- Military

The use of sophisticated tooling allows us to support a diverse range of metal and alloy combinations to meet unique customer needs. We also offer precision wire bonding capabilities and secondary forming services with selective plating.

Custom Metal Bushings

Keats Manufacturing engineers manufacturing solutions for custom metal bushings using precision processes that help reduce friction, minimize noise, and control unwanted movement. Our capabilities span many metal and composite materials, with the ability to incorporate knurl patterns and diamond imprints as needed.

Optimizing our tooling techniques allows us to deliver cost-effective custom metal bushings in various shapes, sizes, and configurations, including:

- Diamond imprints

- Interlocking

- Knurl patterns

- Minimum-to-zero gap

- Split and butt seams

Customers benefit from unsurpassed expertise in maintaining tight tolerances and achieving manufacturing efficiency at Keats Manufacturing. Our state-of-the-art four-slide/multi-slide stamping press technology and quality control processes promote quality for all of our custom bushing products. JIT delivery is also available for our custom metal bushings.

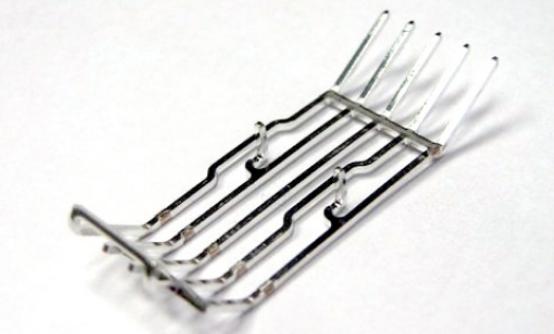

Custom Metal Clips

The team at Keats manufactures custom metal clips for a diverse range of high-performance applications, such as:

- Airbags

- Anti-lock brake systems

- Automotive door panels

- Control systems

- Instrument panels

- Fender assemblies

- Solar panels

- Wire management solutions

- Consumer goods

Our secondary process options include vacuum hardening, austempering, barrel, rack, or selective plating, oil quenching, and other advanced hardening processes to make sure our clips meet demanding industry performance standards. Computational modeling allows us to simulate mechanical stresses to optimize reliability and manufacturability. We work closely with our customers to refine specifications to achieve streamlined production and JIT delivery.

Custom Metal Stamping

At Keats Manufacturing, we specialize in custom metal stamping processes that deliver precision components with minimal waste. By leveraging computational modeling and die stamping, our skilled team can develop a huge selection of custom metal products with consistent quality across various complexities and sizes, from large assemblies to micro-miniature components.

Our production methods include progressive die stamping, stage forming, and four-slide/multi-slide stamping, with the following secondary services seamlessly integrated into the manufacturing workflow:

- Heat treating

- Plating

- Powder coating

- Stress relieving

Customers rely on our expertise to meet high-volume production demands with repeatable, stable metal stamping processes to create quality components, such as:

- Electronic connectors

- Furniture parts

- Fuse clips

- Molding inserts

- Medical components

- Sensor components

- Printer cartridge blades

Custom Lead Frames

Keats Manufacturing is an industry-leading producer of custom lead frames that meet the demands of intricate automotive and microelectronic applications. We offer a comprehensive selection of versatile custom frame products often used to hold microchips.

Our innovative tooling processes allow us to deliver custom lead frames in varying sizes, shapes, and configurations. We also offer selective, precious, and pre-post plating techniques to improve electrical performance and corrosion resistance.

Our secondary forming and wire bonding services ensure each lead frame maintains cost efficiency while adhering to rigorous industry standards. We collaborate with clients to optimize manufacturing strategies, using in-house tooling capabilities to simultaneously produce multiple parts with JIT delivery.

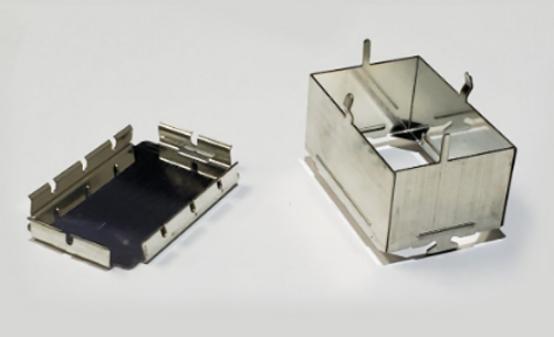

Custom Shields

Keats Manufacturing’s expertise extends to producing custom shields that address mechanical and electromagnetic protection requirements. We design tooling for complex shield sizes and shapes (small, tall, oval, round, etc), integrating features to optimize functionality.

Our processes guarantee compatibility with circuit board and radio frequency applications, delivering consistent results for industrial and technological projects. Our stringent quality control and four-slide/multi-slide stamping presses led by an 18-member team promote quality and consistency in everything we do.

By recommending innovative changes for manufacturability, we help customers across a broad range of industries achieve cost-effectiveness and dependable performance in shield production. JIT delivery is available for our custom shield products.

Custom Wire Forms

At Keats Manufacturing, we develop industry-leading manufacturing solutions for custom wire forms with tight tolerances and reliable precision. We use advanced fabrication techniques to produce wire forms in various shapes, sizes, and configurations for all kinds of wire-form products, such as:

- Fasteners

- Hooks

- Links

- Rings

- Springs

- Terminals

Our products are available in ultra-fine sizes (up to 0.008 inch) with finished tolerances of up to 0.0001 inch, and our processes can accommodate a broad range of metals, from specialized alloys to pre-plated materials to titanium, to guarantee compatibility with precise application specifications.

Clients trust our expertise to refine designs for process scalability and stability. By optimizing the following cutting-edge fabrication steps, we can enhance consistency and efficiency:

- Bending

- Butting

- Cutting

- Flattening

- Straightening

- Stretching

Learn More About Our Custom Metal Products

For nearly six decades, Keats Manufacturing has developed the necessary skills and resources to deliver high-quality custom metal products, utilizing precision manufacturing tools and processes to meet customer-defined specifications. We are committed to innovation and quality, with dependable, repeatable results for customers across diverse industries. Thanks to our tight quality control processes, industry certifications, wide-ranging customization options, and state-of-the-art equipment, our customers are guaranteed the highest level of quality in the custom metal parts they receive.

Contact us today to learn how we can help optimize your manufacturing needs, and download our free eBook for cost-saving tips on improving the turnaround time of your next metal stamping project.