Difference Between Multi-Slide and Progressive Die Stamping

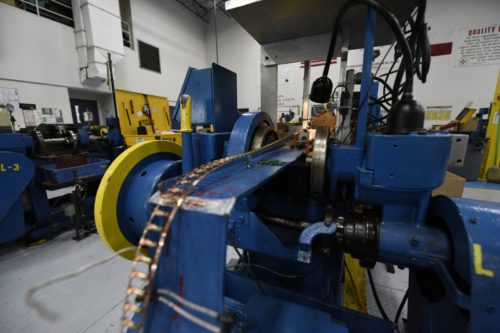

Leave a CommentVarious manufacturing processes require the use of precision metal-stamped products made from slit coil steel, copper, and brass, among other materials. These products are manufactured using power press stamping machines specifically built to produce parts from coiled metal or another similar material.

There is more than one type of stamping machine. The first is the progressive die stamping machine, which allows operations on a piece of metal until a final component is produced. This type of machine combines an automatic feeding system with punching, coining, bending, and other processes for modifying metal raw material and turning it into finished products.

Another type of stamping machine is four-slide/multi-slide stamping machine, which makes possible the production of shapes and bends of varying complexities. This type of machine is used in the mass production of stamped components made from slit coil or wire stock.

Progressive Die Stamping

Progressive die stamping machines use a vertical motion when processing a metal strip. In progressive die stamping, a slit coil metal is fed through a series of stamping stations, each performing a specific operation. The strip begins at the first station, where the die makes the intended cut, bend, or punch. The workpeice then moves to the next station, where the next stamping function is performed. This process continues until the final product is complete and can involve a single step or dozens of steps, based on how complex the design is.

Since each part is attached to the metal strip throughout the formation process, a pilot must be placed into pre-pierced holes to hold the metal in place as it moves through the process. The SMED (Single Minute Exchange of Dies) principles, pioneered by Shigeo Shingo, can be applied to this process. SMED allows dies to be changed quickly and easily to accommodate different designs and is standard practice at Keats.

Advantages

Progressive die stamping has several advantages over other stamping methods, such as four-slide or multi-slide machines.

- Less time to set up: Progressive die stamping takes 38% less time to set up than multi-slide stamping. This allows producers to generate smaller lot sizes and make manufacturing scheduling more flexible to produce what the client wants when they need it. It also reduces the labor involved in the production of parts.

- Repeatability: The machines provide excellent repeatability with tight tolerances. They can generate large quantities of parts without compromising quality.

- High accuracy: Because each station performs a different operation, progressive die stamping is highly efficient and can be used to produce large quantities of parts with a high degree of accuracy.

- Generic Tooling: Because of the simple nature of the forming process, using only vertical pressure, it is possible to move tooling from one supplier to another without the need for a major retrofit. Generally if a press machine of the same tonnage and bed size is available a tool build to run on that bed size and tonnage will be able to run in a different press.

Disadvantages

While there are many advantages to using progressive die stamping for sheet metal fabrication, there are also some drawbacks to consider:

- Expense: One of the biggest disadvantages is the high initial investment cost. Die sets for progressive die stamping can be very costly, and businesses need to be sure that they can generate enough work to justify the expense.

- Limited operations: Progressive die stamping can only be used for certain projects. Some part features may not be possible to produce inside a progressive die.

- Permanence: Finally, progressive die stamping can be very complex and time-consuming (especially since setups have to be configured or reconfigured for each project). This makes it hard to switch between projects quickly.

- More waste: Progressive die stamping produces waste. Due to the fact that the part must be carried on the strip throughout the entire process there is inherent waste caused by the material needed to keep the part on the strip until the very last step. Although the waste material can be recycled, when working with material such as copper or brass this process can be less cost effective.

Four Slide/Multi-Slide Stamping

Four-slide or multi-slide stamping is a process that uses a series of dies and tools to create stamped parts from coils of wire or slit coil stock. The dies are mounted on opposed slides that move in horizontally in four directions (or more for multi-slide stamping), allowing the creation of complex shapes.

The slide stamping process begins with a coil of metal fed into the four slide machine. The machine then uses a series of mechanically actuated cams to stamp and form the metal into the desired shape. Once the stamping and forming is complete, the component is ejected from the press and moves onto the next production stage.

Keats uses multi-slide stamping and forming to make 96% of all clips.

Advantages

Four-slide / Multi-slide stamping offers many advantages over traditional progressive die stamping, including:

- Produces complex parts: Four slide stamping works horizontally on right angles and can create complex or multi-part bends, including those larger than 90°. Multiple folds, bends, cuts, or punches can be completed with a single step.

- Precision and Repeatability: The experts at Keats have spent decades refining the four slide stamping process to ensure the ability to meet the highest quality standard and hold very tight tolerances.

- Burr Side Selection: Because the forming pressure can be applied from any direction it is possible to select if the cutting burr will end up on the top or on the bottom of the strip.

- Less wastage: On average, four-slide/multi-slide machines produce 31% less scrap, leading to significant cost savings. That’s because the process removes the need for pilot holes. It uses slotted blank holders that enable the parts to proceed from stage to stage without pilots. Also, it’s easy to access raw materials in specific dimensions.

- Quick Adjustments: Since all of the forming operations are driven by camshafts it’s possible to make complex and micro adjustments to the tooling without removing it from the machine. This results in less down time and less time in the tool room.

- Flexibility: By changing the dies, various parts can be produced on the same machine.

- Faster and cheaper: In most cases Four-slide stamping faster thank traditional progressive stamping, producing up to 375 parts per minute. This makes it an attractive option for high-volume production runs.

Disadvantages

While the benefits are evident, there are some disadvantages to four-slide/multi-slide stamping.

- Long set up: Slide machines are more complex machines than progressive die stamping presses and can take longer to set up.

- Limited materials: Because of the way they work, four-slide/multi-slide stamping presses can only be used for certain types of metal sheets — those that are thin and flexible. This means that they are not suitable for all applications. Larger parts typically need to be produced by progressive die stamping.

A Summary of Progressive Die and Four Slide/Multi-Slide Stamping

| Stamping Machine | Description | Advantages & Disadvantages |

Ideal for Manufacturing What Parts |

|---|---|---|---|

| Progressive Die | The coiled metal material is fed through the die and is processed progressively in steps. It’s passed from station to station until the part is completed. Source – “Progressive Die Stamping” |

38% less time to setup than four slide/multi slide

Able to produce smaller lot sizes and offers flexibility in production schedule Excess waste and scrap produced because of the need for pilot holes Limits to types of operations that can be performed |

|

| Four Slide/Multi-Slide | Four slide/Multi-slide work in right angles or horizontally. The slides/rams strike the sheet material to produce the final product.

Four slide stamping has four slides but multi-slide can have more than 4. |

Produces 31% less scrap than progressive die stamping

Fast production of small parts with tight tolerances Longer setup time |

Ideal for complex components with high volume requirements

|

Learn More

They may be different, but multi-slide stamping and progressive die stamping each have their own set of advantages. Whatever stamping method is right for your needs, you can be sure Keats Manufacturing Company has the capabilities to provide it for you. We perform a detailed analysis of every RFQ and provide our customers with the most cost effective production solution.

Keats has been providing custom metal stamping, assemblies, and wire forms for over 60 years, and our facilities contain nearly 175 metal stamping and wire forming machines that operate 24 hours a day, 5 days a week. We provide everything from custom prototyping to high-volume orders containing 100’s of millions of parts.

To learn more about our metal stamping processes or other services, contact us or request a quote.

Creating reels of close tolerance terminals and contacts requires advanced stamping techniques. We employ progressive die and four-slide/multi-slide stamping to manufacture enormous volumes of high-precision components (sometimes 20 million or more parts) with the industry’s closest tolerances, including down to ± .001”.

Creating reels of close tolerance terminals and contacts requires advanced stamping techniques. We employ progressive die and four-slide/multi-slide stamping to manufacture enormous volumes of high-precision components (sometimes 20 million or more parts) with the industry’s closest tolerances, including down to ± .001”. Highly efficient and cost effective,

Highly efficient and cost effective,