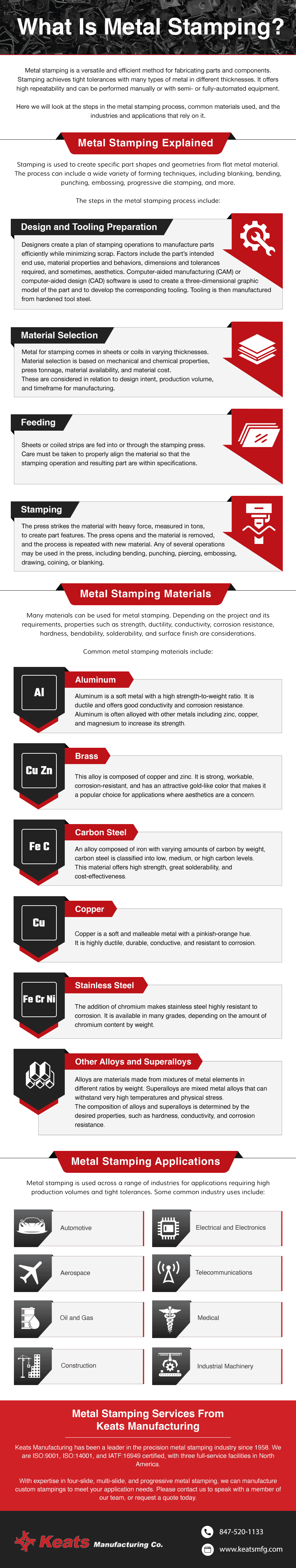

Metal stamping is a versatile and efficient method for fabricating parts and components. Stamping achieves tight tolerances with many types of metal in different thicknesses. It offers high repeatability and can be performed manually or with semi- or fully-automated equipment.

Here we will look at the steps in the metal stamping process, common materials used, and the industries and applications that rely on it.

Metal Stamping Explained

Stamping is used to create specific part shapes and geometries from flat metal material. The process can include a wide variety of forming techniques, including blanking, bending, punching, embossing, progressive die stamping, and more.

The steps in the metal stamping process include:

- Design and Tooling Preparation. Designers create a plan of stamping operations to manufacture parts efficiently while minimizing scrap. Factors include the part’s intended end use, material properties and behaviors, dimensions and tolerances required, and sometimes, aesthetics. Computer-aided manufacturing (CAM) or computer-aided design (CAD) software is used to create a three-dimensional graphic model of the part and to develop the corresponding tooling. Tooling is then manufactured from hardened tool steel.

- Material Selection. Metal for stamping comes in sheets or coils in varying thicknesses. Material selection is based on mechanical and chemical properties, press tonnage, material availability, and material cost. These are considered in relation to design intent, production volume, and timeframe for manufacturing.

- Feeding. Sheets or coiled strips are fed into or through the stamping press. Care must be taken to properly align the material so that the stamping operation and resulting part are within specifications.

- Stamping. The press strikes the material with heavy force, measured in tons, to create part features. The press opens and the material is removed, and the process is repeated with new material. Any of several operations may be used in the press, including bending, punching, piercing, embossing, drawing, coining, or blanking.

Metal Stamping Materials

Many materials can be used for metal stamping. Depending on the project and its requirements, properties such as strength, ductility, conductivity, corrosion resistance, hardness, bendability, solderability, and surface finish are considerations.

Common metal stamping materials include:

- Aluminum. Aluminum is a soft metal with a high strength-to-weight ratio. It is ductile and offers good conductivity and corrosion resistance. Aluminum is often alloyed with other metals including zinc, copper, and magnesium to increase its strength.

- Brass. This alloy is composed of copper and zinc. It is strong, workable, corrosion-resistant, and has an attractive gold-like color that makes it a popular choice for applications where aesthetics are a concern.

- Carbon Steel. An alloy composed of iron with varying amounts of carbon by weight, carbon steel is classified into low, medium, or high carbon levels. This material offers high strength, great solderability, and cost-effectiveness.

- Copper. Copper is a soft and malleable metal with a pinkish-orange hue. It is highly ductile, durable, conductive, and resistant to corrosion.

- Stainless Steel. The addition of chromium makes stainless steel highly resistant to corrosion. It is available in many grades, depending on the amount of chromium content by weight.

- Other Alloys and Superalloys. Alloys are materials made from mixtures of metal elements in different ratios by weight. Superalloys are mixed metal alloys that can withstand very high temperatures and physical stress. The composition of alloys and superalloys is determined by the desired properties, such as hardness, conductivity, and corrosion resistance.

Metal Stamping Applications

Metal stamping is used across a range of industries for applications requiring high production volumes and tight tolerances. Some common industry uses include:

- Automotive: Body panels, brackets, battery contacts, and cover plates

- Electrical and electronics: Clips, tabs, and pins for mobile phones and devices; switches, brackets, terminals, and contacts for appliances and equipment

- Aerospace: High-strength, lightweight components such as panels, cabin equipment, and other parts throughout aircraft

- Telecommunications: Switches, router components, contact plates and tabs, power protection components, cabinets, and enclosures

- Oil and Gas: Connectors, fasteners, brackets, clips, tabs, valves, and metal parts in equipment for oil and gas drilling and exploration applications

- Medical: Parts for implantable pumps and valves, surgical instrumentation, or hardware and panels used in large equipment and furnishings

- Construction: Connectors and fasteners for trusses and framing, braces, brackets, cover plates, and enclosures used in systems throughout buildings

- Industrial Machinery: Components in engines and heavy equipment, tiny parts for electrical systems in machinery, and panels for equipment cabinets

Metal Stamping Services From Keats Manufacturing

Keats Manufacturing has been a leader in the precision metal stamping industry since 1958. We are ISO:9001, ISO:14001, and IATF:16949 certified, with three full-service facilities in North America.

With expertise in four-slide, multi-slide, and progressive metal stamping, we can manufacture custom stampings to meet your application needs. Please contact us to speak with a member of our team, or request a quote today.