Aluminum alloys are grades of aluminum containing other elements that enhance the strength, durability, and other properties of pure aluminum. Adding different alloying elements allows the material to perform in a range of applications.

Elements often added to aluminum include:

- Silicon

- Iron

- Magnesium

- Copper

- Zinc

- Manganese

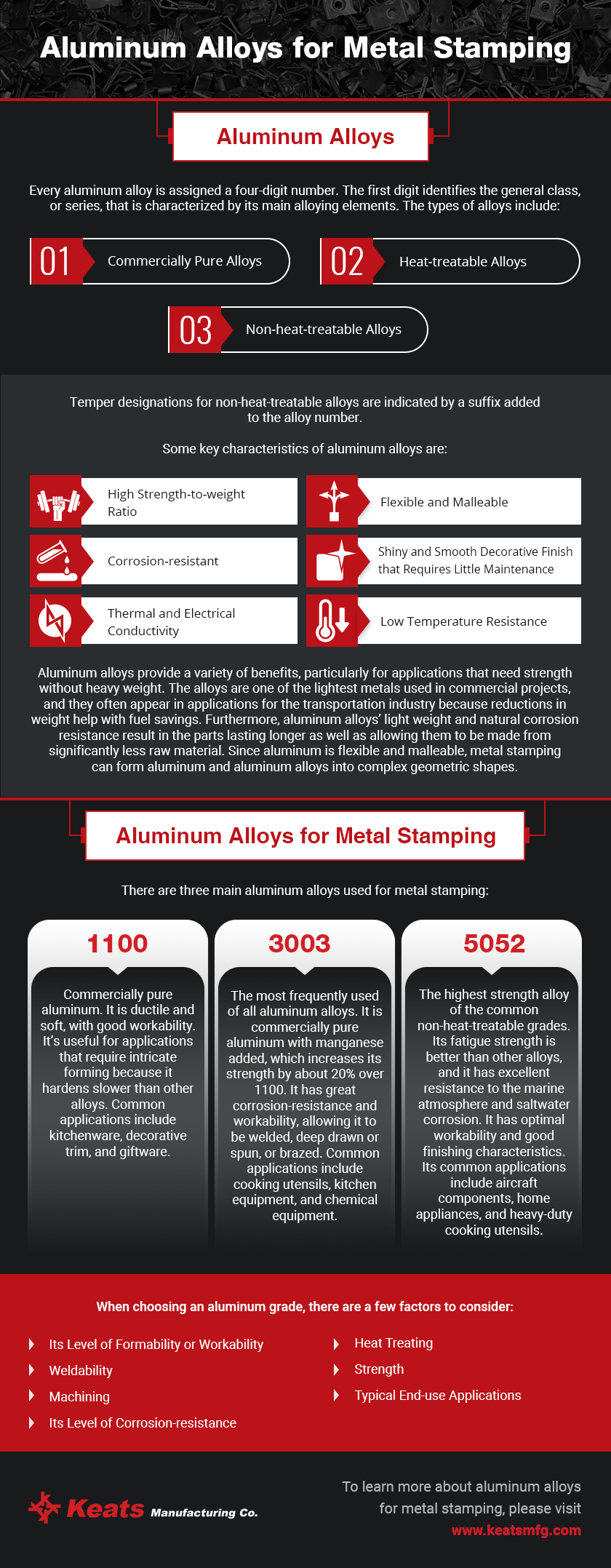

These elements can make up at least 15% of the final alloy by weight. Here we’ll explain the properties and types of aluminum alloys, as well as what makes a good alloy for metal stamping.

What Are Aluminum Alloys?

Aluminum alloys contain aluminum as the predominant metal along with other alloying elements. There are two major forms of aluminum alloys: wrought and cast alloys.

A cast aluminum alloy is an alloy that is melted in a furnace and poured into a mold to cool and solidify. Finished components have a low melting point, and the process creates cost-effective products. However, cast alloys generally have lower tensile strength than wrought alloys. Wrought aluminum alloys are alloys worked in solid form with the help of specialized tools. Aluminum stamping utilizes these alloys, which can be separated into two categories: wrought non-heat-treatable and wrought heat-treatable.

Cast and wrought aluminum have different identification systems. Cast aluminum alloys are identified by three digits followed by one decimal place. Wrought alloys follow a four-digit system, in which the first digit identifies the principal alloying element. The second digit, if not a 0, signifies a modification of the alloy, while the third and fourth digits identify the specific alloy. For non-heat-treatable alloys, a suffix is added to the number to indicate temper designation.

Aluminum Alloy Properties

One of the major benefits of aluminum alloys is their excellent strength-to-weight ratio: they are strong without being heavy. Because they are light, they are often used in commercial projects and transportation applications, where reduced weight results in cost savings.

Since they are light and effective, aluminum alloy parts last longer and require less raw material to make. These and the following characteristics make aluminum alloys ideal for metal stamping operations:

- Thermal and electrical conductivity

- Flexibility and malleability

- Shiny, smooth finish requires little maintenance

- Corrosion resistance

- Strength at low and high temperatures

Types of Aluminum Alloys

There are three types of aluminum alloys:

- Wrought non-heat-treatable

- Made up of high-purity aluminum alloys (1xxx series), manganese alloys (3xxx series), and magnesium alloys (5xxx series), all of which are used for metal stamping

- Hardened mainly through cold working

- Wrought heat-treatable

- Consists of copper, magnesium, or zinc as alloying elements

- Includes 2xxx series, 6xxx series, and 7xxx series

- Precipitation hardening enhances the alloy’s strength

- Cast aluminum alloys

- Includes non-heat-treatable and heat-treatable alloys

- 2xxx, 3xxx, 4xxx, 7xxx, 8xxx series

- Strength levels are not as high as those of wrought heat-treatable alloys

Aluminum Alloys for Metal Stamping

Aluminum is available in various alloys and tempers. The best product varies by project. Here are a few factors to keep in mind when choosing an aluminum grade:

- Level of workability or formability

- Level of corrosion resistance

- Strength level

- Typical applications

- Weldability or machinability

- Type of heat treatment

These are the characteristics and applications of the common aluminum alloys used for metal stamping:

| Aluminum Alloy | Alloying Elements | Characteristics | Common Applications |

| 1100 | Commercially pure aluminum | Ductile and soft

Excellent corrosion resistance Useful for applications that require intricate forming because it hardens slower than other alloys |

Kitchenware, decorative trim, giftware |

| 3003 | Commercially pure aluminum with manganese added | Most frequently used aluminum alloy; inexpensive

Manganese increases strength by about 20% over 1100 aluminum Corrosion resistance Good workability Can be welded, deep drawn, spun, or brazed |

Cooking utensils, kitchen equipment, chemical equipment |

| 5052 | Alloyed with magnesium | Highest strength alloy of the common non-heat-treatable grades

Fatigue strength is better than other alloys Excellent resistance to marine atmospheres and saltwater corrosion Optimal workability and good finishing characteristics |

Aircraft components, home appliances, heavy-duty cooking utensils |

Contact Us for the Top Selection of Aluminum Alloys

For the best turnaround time and price, Keats Manufacturing recommends selecting common gauge and common alloys. Since 1958, we have been crafting stamped metal parts for each client’s needs. We have a strict adherence to our quality control system, ensuring that your customer satisfaction and confidence are our top priority.

Over the decades, unique projects and parts have come through our facility. Decisions for design details and custom tooling influence the performance of the parts, but the material used is always the most critical decision made in the manufacturing process.

To learn more about how we can help with your next project, contact our team. For more information about the materials we use, check out our downloadable eBook, Choosing the Best Raw Materials.

Comments are closed