Compound vs. Progressive vs. Transfer Die

Leave a CommentCompound, progressive, and transfer die stamping are all methods used to produce metal stamped parts for many industries. The three die stamping methods allow manufacturers to meet unique design specifications, tolerances, and volumes, but it is crucial to choose the right process method that meets your needs. Compound Die Compound die stamping is a metal […]

Vehicle / Car Electrical System

Leave a CommentModern cars have a range of electrical connectors and terminals that control the internal system. This complex equipment controls and operates dozens of functions while providing critical real-time information to the driver. As the world makes the transition from ICE (Internal Combustion Engine) to electric-powered vehicles, the technology and components needed to support that transition […]

Key Considerations When Choosing a Metal Stamping Partner

Leave a CommentMetal stamping is a manufacturing process that employs a specialized press, as well as tool and die set, to form sheet metal into a specified shape and size. Industry professionals employ metal stamping processes to produce a wide range of industrial parts and products. When looking for a metal stamping partner, there are several considerations […]

Tags: metal stamped parts, metal stamping, metal stamping partner, tooling

Is Precision Metal Stamping Right for Your Application?

Leave a CommentPrecision metal stamping is a manufacturing process that utilizes a custom tool and die set installed in a stamping press to turn sheet metal into the desired components. It is used in a wide range of industries to create large quantities of parts and products with high precision, accuracy, and speed. While this process offers […]

Tags: custom metal stamping, custom stamped metal components, high-precision components, metal stamped parts, metal stamping, precision machined components

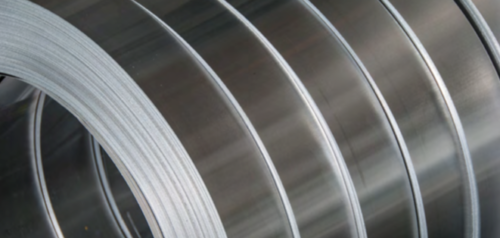

Aluminum Alloys for Metal Stamping

Leave a CommentAluminum alloys are grades of aluminum containing other elements that enhance the strength, durability, and other properties of pure aluminum. Adding different alloying elements allows the material to perform in a range of applications. Elements often added to aluminum include: Silicon Iron Magnesium Copper Zinc Manganese These elements can make up at least 15% of […]