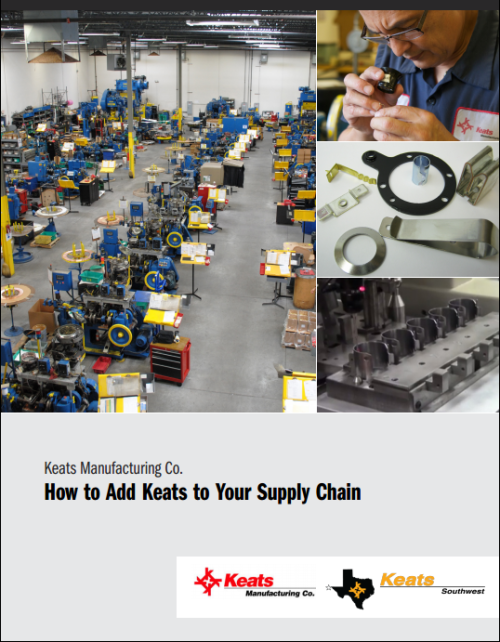

Over more than 50 years in business, Keats Manufacturing Company has built a strong reputation of unsurpassed product quality and excellent customer service. This reputation is one that spans industries, sectors, and customers.

Our world class customer service team is responsible, in part, for our exemplary reputation — they are highly knowledgeable, responsive to our customers’ needs, mind all of the details, and focus on long-term relationships as opposed to sales figures.

Our world class customer service team is responsible, in part, for our exemplary reputation — they are highly knowledgeable, responsive to our customers’ needs, mind all of the details, and focus on long-term relationships as opposed to sales figures.

Equally important is part quality. Even the best customer service can only do so much in the face of substandard quality. To maintain the high level product quality that drives our reputation, Keats works hard to stay informed of the constantly evolving technological landscape.

At both our main facility in Wheeling, IL, and our Keats Southwest facility in El Paso, TX, we employ a range of state of the art technology to ensure that we manufacture and deliver only the highest quality products possible.

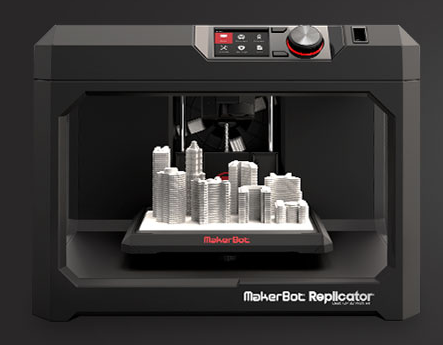

3D Printers

Keats Manufacturing Company’s dedication to quality starts at the design and prototyping stage. We are equipped with cutting edge 3D printers — these tools are used not for production, but for prototyping.

The ability to produce full size part models quickly and inexpensively is invaluable. These prototypes allow us and our customers to inspect parts before beginning full-scale production, allowing us to correct errors and make improvements when it is easy and least expensive to do so. Through the use of this technology, not only will your product be of a higher quality, it will get to the market faster.

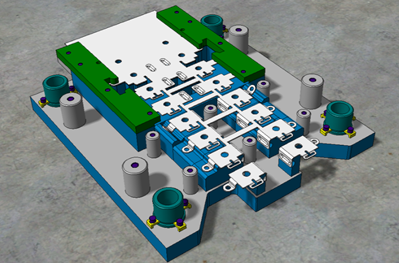

AutoCAD and 3D Visualization

When your prototype is approved, we use the most modern AutoCAD software to finalize its design and 3D die visualization software to design the tooling components your part will require.

When your prototype is approved, we use the most modern AutoCAD software to finalize its design and 3D die visualization software to design the tooling components your part will require.

These two pieces of software help us plan the production run of your part, minimizing waste and raw material requirements, and develop tooling that balances performance with cost considerations.

Process Automation

Wherever possible, Keats integrates automation into our manufacturing and assembly processes. In both of our facilities, screw insertion and contact insertion have been automated, as has staking. Staking is a type of contact insertion wherein a emboss on one piece is inserted into a hole in another — the emboss is axially compressed, forming a permanent interference fit Joint.

Wherever possible, Keats integrates automation into our manufacturing and assembly processes. In both of our facilities, screw insertion and contact insertion have been automated, as has staking. Staking is a type of contact insertion wherein a emboss on one piece is inserted into a hole in another — the emboss is axially compressed, forming a permanent interference fit Joint.

Keats also automates screw insertion and hole threading/tapping. This process is fully automated through advanced production equipment that threads/taps holes in stamped parts as well as inserts a screw into the threaded hole. The screw is torque checked in-line and a digital readout is displayed before the finished part is ejected from the machine.

Process automation increases our production capabilities, allowing us to accommodate larger production runs with ease, while keeping your costs reasonable.

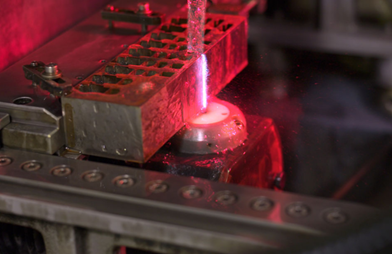

Rotowire Chamfering

Common in mechanical and manufacturing engineering, a chamfer is a transitional edge between two faces of an object sometimes known as a bevel.

A value added automated process, we have seamlessly integrated rotowire chamfering into our manufacturing process — it allows for one-piece flow manufacturing in place of the multiple steps that would have been required in the past.

Wire EDM

Wire EDM allows us to manufacture highly complex shapes with unique geometries and maintain extremely precise tolerances. It works with materials of all types and is automated and fully CNC controlled. At Keats, we primarily use our wire EDM capabilities for the quick and precise manufacture and maintenance of tools and dies.

At Keats Our 2 state of the art wire edm machines allow us to respond extremely fast to any tooling malfunction issues. In the event of a tool component failure, a replacement component can be replicated in-house within a matter of hours. All of our tools are built with insert-able cutting and forming stations allowing us ease of maintenance and quick adaptability to customer driven part changes.

Work with Keats

To learn more about Keats and why we should be part of your supply chain, download How to Add Keats to Your Supply Chain for free today.