Keats Manufacturing Achieves IATF 16949:2016 Certification

Comments Off on Keats Manufacturing Achieves IATF 16949:2016 CertificationKeats Manufacturing is pleased to announce that we have achieved certification under IATF 16949:2016, a technical specification for quality management systems in the automotive sector as set forth by the International Automotive Task Force (IATF). What is IATF 16949:2016 certification? A Quality Management System (QMS) is a set of processes, policies, records, and documented procedures […]

Pre-Plating, Post-Plating & Selective Plating: What’s the Difference?

Comments Off on Pre-Plating, Post-Plating & Selective Plating: What’s the Difference?The plating process involves adding layers of metal onto existing workpieces, and can allow for a wide range of performance benefits depending on the specific application. Various techniques and materials can be used to create unique end products, but the wide range of options can often be daunting. We’ve outlined some of the main benefits […]

Tags: metal plating, plating

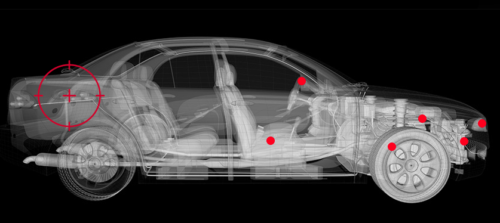

Metal Stamped Parts for the Automotive Industry

Comments Off on Metal Stamped Parts for the Automotive IndustryThroughout our more than 50 years of business, the engineers at Keats Manufacturing have been producing the highest quality custom metal stampings, wire forms, and assemblies for a wide range of industries. Listed below are several examples of custom metal stamped parts for automotive that Keats has manufactured. Positioning Sensor for Steering Wheel Keats was […]

How Electrical Terminals Are Used in the Auto Industry

Comments Off on How Electrical Terminals Are Used in the Auto IndustryIn today’s vehicles, almost all internal systems are controlled by an array of electrical terminals and connectors. These increasingly complex devices govern dozens of onboard functions, engine controls, safety features, and infotainment platforms — all while delivering critical feedback to the driver in real-time. What are electrical contacts and terminals? A network of electrical contacts […]

Tags: automotive, electrical terminals

Keats to exhibit at Mexico’s Automotive Meetings Trade Show and Mexico’s Manufacturing Supply Chain Summit

Comments Off on Keats to exhibit at Mexico’s Automotive Meetings Trade Show and Mexico’s Manufacturing Supply Chain SummitFrom February 20-22, Keats Manufacturing will be exhibiting at Automotive Meetings, the annual international automotive manufacturing forum. Held at the Queretaro Congress and Convention Center in Queretaro, this exciting event — the only auto supply chain event in Mexico — brings together industry-leading OEMs from across the globe. The team at Keats Manufacturing is also […]